Alumamark : quality photo images on real metal

The only Co2 laser marking real metal material

Materials and supplies needed

Co2 marking / engraving laser

A Co2 laser is necessary to process Alumamark or Durablack.

We offer a wide range of laser: plotter type lasers ( LTT industrial range , EKO range ) and galvanometric type lasers (galvanometric C02 lasers).

Find the whole range in the laser engraving section of our site.

Applications

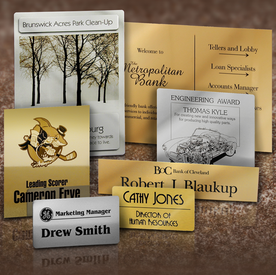

Diplomas, awards, prizes ... in Alumamark

Distinction, employee of the month, awards ... made in a few minutes on Alumamark

Labels, plates, product name, awards in Alumamark

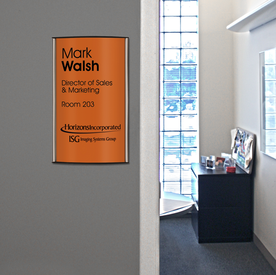

Identification of employees, employee badges, door signs ... quickly produced with Alumamark

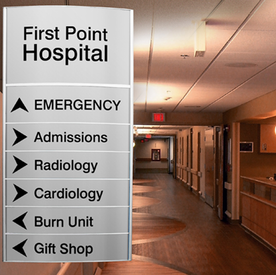

Signage,panels, indications, ... quickly produced in Alumamark

Directions, instructions ... in Alumamark

Memorial, awards, name plates in Alumamark

Manufacturer plate, serial number, bar code in Alumamark

Reproduction of newspaper articles, art paintings.... on Alumamark

Internal building signage in Alumamark

Videos

Faq

Should you try and mark / engrave aluminum with a Co2 laser, you will note that reflection of the laser beam on metal makes marking impossible.

With Alumamark, marking aluminum with a Co2 laser is now possible : the aluminum sheet includes a special sensitive layer that absorbs the Co2 wavelength (10.6 microns) to produce a black marking.

AlumaMark represents a major technological advance as it is no longer necessary to coat /spray substrate with marking product such as Cermark or Thermark

Typical applications include trophies, panels, manufacturer plate, diagrams... and common one is UID barcodes.

AlumaMark ™ is a positive transforming material that produces varying shades of black and high detailed image reproduction when in contact with the laser beam spot.

It is available in a variety of metallic silver, gold, brass and bronze finishes and solid colors.

All finishes are available in 305 x 508 mm and 0.5 mm thickness.

Silver, gold and brass colors are also available in 508 x 610 m sizes.

A very thin flexible sheet (0.13 mm) is available in silver and gold and in a five color pack.

Satin silver produces a particularly good finish for photographic reproductions.

AlumaMark is intended for indoor use. For outdoor use, a UV blocking overlaminate or spray must be applied.

Durablack and Alumamark are two Co2 lasers imaged real metals.

Both have similar characteristics in terms of reproduction sharpness , speed and ease of use, but marking results and final uses are different.

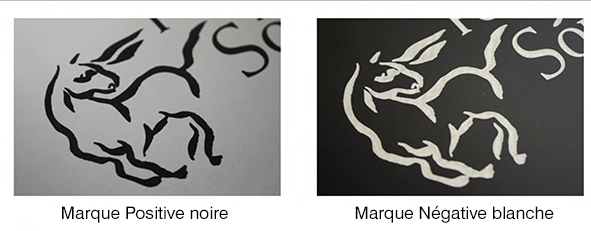

On Durablack : the laser spot will produce a white mark on the black background, result being close to engraving although there is no hollow. Marking is in negative (aluminum on black)

On Alumamark : the laser spot will produce a black mark by chemical transformation of the plate surface. Marking is in positive (black on aluminum)

In terms of durability, Alumamark is meant for indoor use (varnish or protective film required for outdoor use), while Durablack is designed for outdoor applications and complies with major industrial and military specifications.

More and more engraving companies are using metals for elegant applications such as corporate awards, diploma reproductions, newspaper reproductions, industrial labels and signage.

Contrary to common idea , laser-markable metals are sometimes less expensive than engravable plastics. In case they are , additional cost may not be a problem if added value (elegant look, durability, etc.) of metal allows to increase selling price.

Alumamark is the unique solution allowing to mark a real metal in positive (black on aluminum) with a CO2 laser.

Laser Markable Metals (LMM) refer to materials that appear metallic and can be marked with a CO2 laser. Fiber lasers and Yag lasers mark some metals but are more expensive and less common

DIFFERENT REACTIONS ON LMM

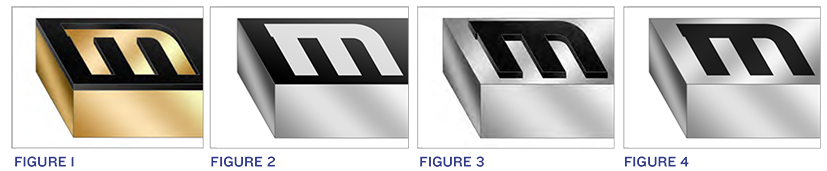

According to marking results with a CO2 laser, LMMs are classified into 4 groups :

Engraving : Color surface is removed or burnt by laser (FIGURE 1).

Examples: Rowmark, Metalgraph Plus, IPI LaserMetallic Brush, lacquered aluminum, DuraBlack

Whitening : Metal turned white by laser heat (FIGURE 2).

Examples: Black anodized aluminum , LazerWhite.

Ceramic bonding : A coating is applied (brush, spray) on the metal and fixed by the heat of laser (FIGURE 3).

Examples: CerMark, TherMark

Positive image transformation : pre-coated metal is marked by a surface chemical transformation (FIGURE 4).

Examples: AlumaMark and laserable anodized mirror aluminum (LAMA)

METAL CHOICE

Each metal and each marking method has its own advantages and disadvantages, the most important being the finished product rendering. No matter for your customers how the plate is engraved as long as the finished product meets their expectations.

When selecting a LMM, 3 points should be taken into account :

1. Basic material : LMMs are made of aluminum, steel, brass or even metal looking plastic Proper material should be chosen according to customer's needs.

2. Marking type : : most LMM appear metallic, although some just include a metallic paint.

When imaged with a CO2 laser, some form a black “positive” mark (black mark on a metallic background) and others are imaged up to a white “negative” mark (white mark on a black or metallic background).

Select material that creates appearance requested by your customer.

3. Durability : It is a common idea that something made of metal is durable. This is simply not the case for LMMs. Some are specified for outdoor use, others not. When choosing a durable LMM, be sure that it is meant for outdoor use. If you plan to work with industrial or military suppliers, make sure your LMM meets military specifications (Durablack).

Depending on all above points (Metal / Plastic, Positive or Negative Marking, indoor / outdoor use) you can choose appropriate material.

The most common misconception about laser-markable metals is that they are all real metal. In fact, many of so-called "laser-markable metals" are not metal at all, but extruded plastic.

Real metal and metallic looking plastic have both their place in various applications; however, it is good to know that metallized plastic may not look like the real metal that many customers expect.

Alumamark is a real Metal.

Over the years, some difficult-to-use laser-markable metals have produced bad effect , leading to no longer use them.

Using Alumamark is easy, without any additional operation.

Ten years ago, laser-markable metals were almost twice as expensive as plastic.

Today, many laser-markable metals cost the same price or even less than engraved plastics. When you consider the more important feeling for metals, it becomes clear that laser-markable metals are not only cost competitive, but can generate more benefits for your company.

Just look at Alumamark price list ; you may be surprised by what you find.

Power and speed settings are essential when using AlumaMark. Initially, you will need to test and find the "ideal point" settings for your laser.

Generally, low power (5-15 W) and high speed are recommended, combined with high resolution (1000 dpi).

A 2 "or 1.5 " lens is ideal.