What is engraving?

Laser engraving / cutting / marking can be made by means of

2 types of source: Co2 or fiber source

2 types of guiding system : plotter or galvanometric type

Co2 lasers are gas lasers, with a 10.6 micrometer wavelength for non-metallic material applications. With a high versatility, they are widely used in plastics, wood, cardboard, fabrics, glass, leather, stone… applications.

Fiber lasers are solid-state lasers with a 1,064 micrometer wavelength. The laser beam is 100 times more powerful than a same power Co2 laser beam. It is specially used in metal cutting applications and in metal or plastic marking applications with various contrasts (grey to black)

Plotter type guiding system : The laser beam is driven onto the material by means of fixed mirrors mounted on two axis that moves in X and Y directions. This type of guidance is slower than galvanometric one but allows larger cutting/engraving surface (the larger the machine, the larger the engraving surface).

Galvanometric type guiding system (used in both Co2 & fiber lasers) the laser beam is driven onto the material by mobile mirrors moving in X & Y directions. Each set of XY mirror is independently connected to extremely accurate, reproducible and fast galvanometer motors. With this kind of guiding system, cutting/engraving surface is smaller than with plotter type guiding system.

Our range of laser machines includes all above techniques.

Our range of engraving equipment

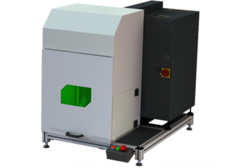

OEM model fiber laser

OEM laser for integration into production lines.

Available in different powers from 12 to 50 w and different marking areas from 70 x 70 mm to 300 x 300 mm.

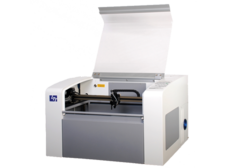

Fiber Mark Pro 3 fiber laser

Fiber Mark Pro 3 model offers a complete, independent, evolutionary and easy-to-use marking station.

Available in different powers from 30 to 50 w and different marking areas from 70 x 70 mm to 300 x 300 mm.

Fiber Mark Basic fiber laser model with pendular table

FiberMark laser with pendular table allows to automatically insert the part to process (automatic drawer).

Once processed, the part automatically comes out to be replaced by a new one by operator

3 powers are available from 20 to 50 w with different marking areas, from 70 x 70 mm to 300 x 300 mm.

Fiber Mark Pro Max-I fiber laser with turning table

Pro MAX I version brings productivity to Fiber Mark laser.

A turning table allows to engrave a part while operator is loading another one. When engraving is completed, the table turns, operator removes the engraved part and loads a blank one, while the previous one is being processed.

Powers available from 30 to 50 w and marking areasfrom 70 x 70 mm to 300 x 300 mm.

Fiber Mark Pro Max-XY segmentation fiber laser

Just imagine the speed of a galvanometric laser with the surface of a laser plotter!

Pro MAX XY workstation is equipped with two X and Y axes which allowing to move the laser source. As a result, the size of marking / engraving / cutting can go up to 1000 x 500 mm.

The galvanometric head movement is automatically managed by the software and transparent for operator.

The cutting area is divided into 220 x 220 mm sections.

Available powers go from 30 to 70 w.

V2000 Co2 engraving / cutting laser

V 2000 model is a Co2 cutting/engraving laser, equipped with a US radio frequency laser tube.

Working sizes are 450 x 310 mm with a maximum height of 150 mm.

With reduced sizes and openable door, it can process materials of 310 mm x infinity

.

V3000 Co2 engraving/cutting laser

With working sizes of 610 x 420 mm and max. height of 150 mm, V3000 laser is equipped with a US RF Co2 laser tube.

Available in 30, 40, 60, 80 or 100 W according to the power you need.

ILS3V CO2 engraving/cutting laser

ILS3 V is a stand model laser, with working sizes of 660 x 495 mm x 210 mm maxi height.

Front/back openable doors allow to process materials of 660 x mm x infinity

Available in 30,40,60,80 or 100 W according to the power you need.

I3000 CO2 engraving/cutting laser

With 700 x 500 mm working sizes, 230 mm maximum Z axis height and back/front/right/left openable doors , a multitude of applications is possible with the sole limit of 700 mm

Available in 30, 40, 60, 80 or 100 W according to application required power.

I4000 CO2 engraving/cutting laser

I 4000 is the largest model of our industrial range of Co2 engraving/cutting lasers, with working sizes of 1000 x 600 mm x 230 mm max height and front/back/right/left openable doors.

Available in 30, 40, 60, 80 or 100 W powers.

Eko 5 CO2 laser cutting/engraving laser

Eko 5 laser is a versatile, economical and efficient CO2 machine equipped with a glass laser tube.

Working sizes: 500 x 300 mm x 120 mm height

Several tube powers are available according to your applications.

Eko 7 Co2 cutting / engraving laser

Eko 7 is the best-selling model of EKO range of lasers.

Working size : 700 x 450 mm

Z axis adjustable from 0 to 150 mm.

Available in 40, 60 or 80 w.

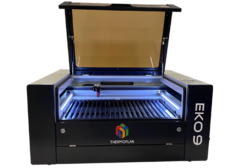

Eko 9 CO2 cutting/engraving laser

With 900 x 600 mm working sizes and 150 mm part height, EKO 9 can be used in a wide range of applications for an affordable cost.

Available in 40 / 60 / 80 or 100 W

Eko 10 CO2 cutting/engraving laser

With 1000 x 700 mm working sizes and 200 mm part height, EKO 10 is ideal for both cutting and engraving applications.

With front/back opening doors, it is possible to process large sized materials : 1000 mm x infinite

Available in powers from 75 to 100 W

Eko 14 CO2 cutting/engraving laser

Cutting sizes of Eko 14 are 1400 x 900 mm x 200 mm height, .

Front / back opening doors allow to process large materials of 1400 mm x infinity.

Available in several powers from 90 to 130 w

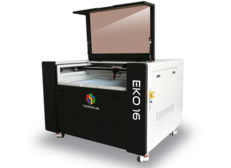

Eko 16 CO2 cutting/engraving laser

With cutting sizes of 1600 x 1000 mm and 200 mm height, Eko 16 is the largest model of EKO lasers .

Front / back opening doors allow to process large materials of 1600 mm x infinity.

Available in several powers from 90 to 130 w

Cmark OEM Laser

OEM laser for integration into production lines.

Available in different powers from 12 to 100 w and different marking fields from 70 x 70 mm to 300 x 300 mm.

C MARK laser with PRO STATION

In the PRO3 version the Cmark laser (CO2) is integrated in a closed workstation (class 1).

Depending on your applications the PRO3 station is available in different power ratings from 12 to 100 W and different marking fields from 70 x 70 mm to 300 x 300 mm.

C MARK laser WITH PENDULUM TABLE Galvanometric CO2 marking laser

CMark laser with its pendulum table allows the part to be automatically moved into the lasering area for engraving (automatic drawer).

Once engraved, part automatically comes out for replacement by a new one by operator.

5 powers are available from 12 to 100 w with different marking areas from 70 x 70 mm to 300 x 300 mm.

CMARK with Pro MAX I Station Co2 galvanometric marking laser

Pro MAX I version adds productivity to CMark laser.

A turntable allows to engrave a part while the operator loads another. When 1st part engraving is completed, the table turns, so that operator can remove engraved part and load a new one, while previous one is being marked.

Available in several powers from 12 to 100 w and different marking areas from 70 x 70 mm to 300 x 300 mm.

Pro MAX XY galvanometric CO2 marking laser

Imagine the speed of a galvanometric laser with the surface of a laser plotter !

The Pro MAX XY workstation is equipped with two X and Y axes that moves the laser source. Marking / engraving / cutting sizes can thus go up to 1000 x 500 mm.

Galvanometric head movement is automatically controlled by the software and transparent for operator.

Overall cutting area is divided into smaller areas corresponding to focal length used : 112 x 112, ..., 300 x 300.

Available powers from 12 to 100 w.

3 Axis CO2 Galvanometric laser

The 3-axis Co2 laser is available in several powers 70, 150, 200 w according to your applications.

As standard, the 3rd axis allows you to engrave / cut surfaces of 600 x 600 mm.

Other sizes can be studied on request.

3 Axis CO2 Laser with pendulum table

Identical to the C6060, the pendulum table version improves productivity by using a two-position table : one work piece is engraved while the other is loaded.

Available in 70, 150 and 200 w in 600 x 600 mm

Advantages and uses of the process

Used in engraving, marking or cutting applications, laser generates a high energy that will heat or vaporize material at the focusing point, with the following advantages :

- No physical contact with material : no need for template , no risk of tool wear or breakage (saw, drill…)

- Very thin impact point (about 100 microns) providing very high accuracy

- High versatility : according to Co2 or fiber technology, most material can be laser-processed : plastic, wood, leather, cork, metals, cardboard,...

- Environment friendly engraving/marking (no need for ink, solvents, screen cliche..) directly inside the material and thus unalterable to the wear of time

- Easy integration in production line : fiber or Co2 galvanometric lasers are particularly easy to integrate into manufacturing lines for traceability or product identification.