What is a fiber laser ?

Fiber laser is another type of laser source with different wavelength from Co2 lasers.

Close to infrared (1.064 micrometers), the laser beam is particularly small (10 x smaller than a Co2) with a very high intensity (up to 100 times higher than a same power Co2 laser) to mark on metal, plastics and even ceramics.

Fiber lasers also offer minimal maintenance and a very long service life (100,000 hours).

Fiber lasers are used in many sectors : electronics, industries, jewelry, cars, plastics, etc.

Fiber lasers offered by Thermoflan are available in different configurations : for integration into a production line or workstation, or in large version by segmentation with ProMax XY model.

Our range of fiber lasers

OEM model fiber laser

OEM laser for integration into production lines.

Available in different powers from 12 to 50 w and different marking areas from 70 x 70 mm to 300 x 300 mm.

Fiber Mark Pro 3 fiber laser

Fiber Mark Pro 3 model offers a complete, independent, evolutionary and easy-to-use marking station.

Available in different powers from 30 to 50 w and different marking areas from 70 x 70 mm to 300 x 300 mm.

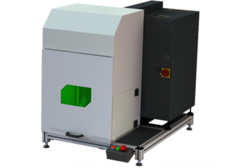

Fiber Mark Basic fiber laser model with pendular table

FiberMark laser with pendular table allows to automatically insert the part to process (automatic drawer).

Once processed, the part automatically comes out to be replaced by a new one by operator

3 powers are available from 20 to 50 w with different marking areas, from 70 x 70 mm to 300 x 300 mm.

Fiber Mark Pro Max-I fiber laser with turning table

Pro MAX I version brings productivity to Fiber Mark laser.

A turning table allows to engrave a part while operator is loading another one. When engraving is completed, the table turns, operator removes the engraved part and loads a blank one, while the previous one is being processed.

Powers available from 30 to 50 w and marking areasfrom 70 x 70 mm to 300 x 300 mm.

Fiber Mark Pro Max-XY segmentation fiber laser

Just imagine the speed of a galvanometric laser with the surface of a laser plotter!

Pro MAX XY workstation is equipped with two X and Y axes which allowing to move the laser source. As a result, the size of marking / engraving / cutting can go up to 1000 x 500 mm.

The galvanometric head movement is automatically managed by the software and transparent for operator.

The cutting area is divided into 220 x 220 mm sections.

Available powers go from 30 to 70 w.

Advantages and uses of fiber lasers

Main advantages of our Fiber lasers are:

- their high performance galvonometric head providing very high speed material marking

- a reduced maintenance : only the lens is to be cleaned from time to time.

- an extended life time of the laser beam : more than 100,000 hours

- significant flexibility, with an industrial software making possible automatic data incrementation, external data pickup, QR code management, etc.

- wide versatility in material engraving / marking : ceramic, aluminum, silver, gold, steel, stainless steel, brass, plastic (PA, PC, PE, PES, PET, PS, PP…) and cutting of some metals with small thickness (aluminum, brass, gold, silver, copper)

- a wide range of machines according to specific needs : single head for integration, independent working station, station with pendulum table or turntable for higher productivity, station with larger working area by segmentation.