What are pad printing accessories ?

Thermoflan, in partnership with the best actors on the market, offers all necessary products and equipment for quality pad printing.

Products : silicon pads, Printcolor® inks, steel / water / alcohol / laser processed clichés, molding paste…

Equipment : UV exposure units, Corona pre-treatment unit, post-treatment unit, drying tunnel, cleaning machine…

All the above selected from our own experience in the matter and from our customers’ feedback.

Our range of pad printing accessories

UV MARK uv exposure unit

UV unit for exposure of pad printing cliche up to 255 x 305 mm.

UV Mark GF Exposure unit

UV unit for exposure of pad printing cliche up to 550 x 350 mm.

Automatic machine for cliche processing

Combined machine for automatic production of water processed plates ((exposure / development / drying)

maximum size = A 4 (210 x 297 mm).

Cliches and developer for pad printing

We can offer a large range of cliches: alcohol processed, water processed, steel etched or laser engraved cliches.

All are available in several sizes , for our own equipment as well as other machines.

Pad printing inks

As a partner of Printcolor Swiss company, we can offer a wide range of inks to suit printed substrate requirements

Pad printing silicon pads

Wide choice of silicone pads : shape, hardness or durability... suitable for any model of pad printing machine.

1 or 2 component fixing paste

Used to easily create a jig holding the parts to print.

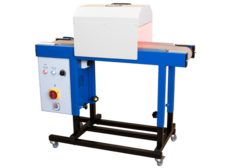

Infra red drying tunnel

Our infra red tunnels accelerate ink drying by evaporation of solvents.

They are available in several widths and lengths

Corona treatment for pad printing

Corona treatment consists of an electric discharge that will transform the material state and make it permeable to inks.

It is necessary for some plastics with a poor surface tension.

cleaning machine for pad printing ink cups and accessories

On the same principle of a washing machine, it cleans all pad printing elements in contact with ink : ink cups, spatulas, doctor blades...

Advantages in using these products

All above products and equipment had been selected to comply with our machines. Using them secures a flawless production with no loss of time or material.

Our technical department will guide you in using these elements to quickly get quality prints.