Enter the customization market

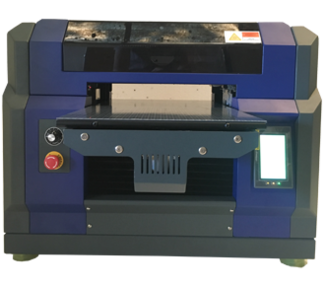

with FB 3300 SC solvent flat bed digital printer

Models

Documentation

Download

Faq

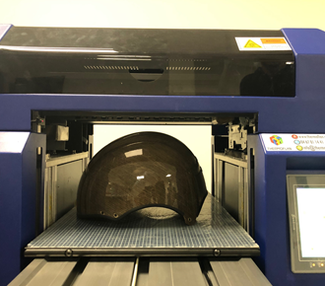

FB3300 SC is an inkjet printer equipped with a 320 x 550 mm platform on which parts to be printed are placed

A 17 cm printing height (maximum part thickness) makes a wide variety of applications possible.

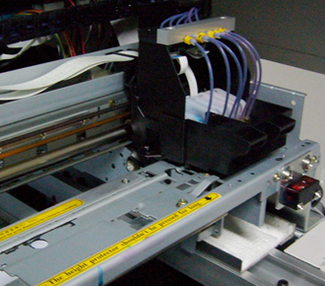

When artwork, designed in the graphic software, is sent to the machine, printing head moves and spays inks onto the product surface, while platform moves back and forth.

To prevent inks from spreading, a temperature controled heating module evaporates solvents from ink and fix marking on printed item.

Main interest of FB3300 SC is the possibility to print on porous aluminum developed for digital and allowing to produce good durability panels, labels, signage, bar codes .. without chemical etching or screen printing technical constraints.

Solvent printing has some limitations:

- It is not possible to print on too convex or concave or irregular surfaces. Print head moving 2 mm above part surface, nothing should obstruct its movement. In case printing part is not perfectly flat, marking accuracy may be impaired when distance between head and printed surface exceeds 4-5 mm

Note: it is however possible to print golf or ping pong balls or pen bodies, reducing their marking surface (example 21-22 mm for golf ball)

- inks available are Cyan, Magenta, Black, Yellow, Blue and Red. White color not being available, it is therefore impossible to print on dark media.

- some products require the application of a primer so that ink can adhere to the support.

FB 3300 SC can be equipped with a rotation device to print cylindrical parts.

Printing speed depends on expected print quality, marking sizes and empty spaces (blank areas are "skipped" by the machine), ink drop size and lamp management mode.

Only tests allow to validate actual output according to desired results. We are at your disposal to carry out tests in our show room.

Printing cost : it is very low and depends on printed surface and filling rate.