AlumaJet® : full color photo quality images onto real metal with a standard ink jet printer

AlumaJet® : full color photo quality images onto real metal with a standard ink jet printer

Applications

Employee badge, exhibition badge, ... in inkjet printable aluminum Alumajet

Office decorations, art paintings, landscapes, ... in inkjet printable aluminum Alumajet

Diplomas, winning prizes, awards, ... in inkjet printable aluminum Alumajet

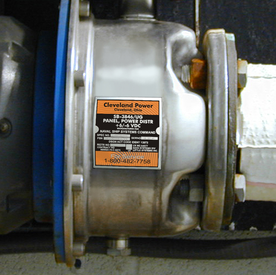

Manufacturer labels, nameplates, serial number, ... in inkjet printable aluminum Alumajet

Name labels, badges, office signage ... in inkjet printable aluminum Alumajet

Restaurant menu, signs, decorations, ... in inkjet printable aluminum Alumajet

Decorations, portraits, art paintings, reproductions ... in inkjet printable aluminum Alumajet

Price labels, product descriptions ...in inkjet printable aluminum Alumajet

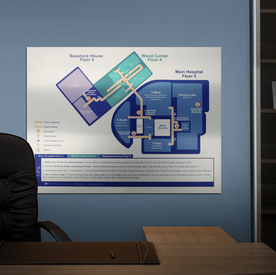

Orientation plans, fire plans, maps, ... in inkjet printable aluminum Alumajet

Award panels, distinctions....in inkjet printable aluminum Alumajet

Videos

Faq

Alumajet allows you to make very attractive aluminum prints, without special operations (as if you were printing on paper), and without significant investment because it can be processed on a standard inkjet printer

AlumaJet is an ideal substrate for reproducing precise colors and fine details of vector and bitmap images as well as very small texts. This is a main point that sets AlumaJet apart from other printing and transfer methods.

Over the years, AlumaJet has been used in many color reproduction applications, especially when fine details are required, such as posters, award plaques, reproductions of magazine and newspaper articles, photographs, diplomas / certificates, control panels, product / equipment labels, warning labels, badges names, nameplates, wiring diagrams , diagrams, memorials and much more

The AlumaJet printing process is easy, reliable and affordable because it works with many standard off-the-shelf ink jet printers

Printing on AlumaJet is very similar to printing on photo paper. Because compatible printers are water-based, inks can sit idle for months and still get good results upon start up. Unlike dye-sublimation, AlumaJet requires no transfer paper or heat presses.

Compared to UV-cured ink jet systems, the AlumaJet compatible printers cost a fraction of the price.

It is as easy as printing on photo paper with your inkjet printer:

- typeset the artwork : panel, signage, trophy ...

- load the Alumajet sheet in the printer (choosing proper thickness according to printer)

- Print the sheet

NOTE: if product goes in an harsh condition environment (water, UV, solvents, abrasion ...) it may be necessary to add a protective overlam or varnish.

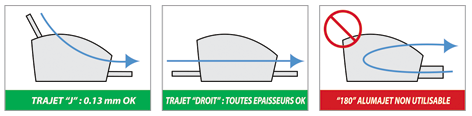

3 Kinds of printer are available on the market :

"J" path : paper is placed in the upper part and prints out on the front panel. It describes a "J" path. 0.13 Alumajet mm is suitable.

"Straight" path . The paper is horizontally placed behind and comes out on the front without deforming. 0.13 and 0.3 mm Alumajet are suitable.

"180" path : Alumajet cannot be printed.

Some suitable printers of the market :

- Epson Stylus Pro 3800 and 3880

- Epson Stylus Pro 4880

- Canon Pixma 9000 & 9500

- HP B9180

- Epson R800/R1800

- Canon IPF 5000 & 6000 Series

- Epson Stylus Pro 7880

- Epson SureColor P800

AlumaJet is mainly meant for indoor uses.

AlumaJet sheets printed with premium pigment inks are expected to last several generations indoors.

For outdoor use, protective overlams and varnishes are available. Their UV blocking properties can extend outdoor life of AlumaJet in most environments for 3-5 years or more.

Blank AlumaJet sheets should be kept in their black protective envelope as long as they are not used.

When loading the sheet in the manual feed tray of the printer, hold the sheet by the edges and avoid touching the printable surface. Wearing cotton gloves is advised to eliminate the possibility of fingerprints on the imaged surface.

Once the sheets have been printed, let them dry completely before stacking, handling, covering or laminating them. Drying time can be reduced using a hair dryer or a heat gun set at lower

Once printed, a protective sheet or aerosol varnish is required to protect the AlumaJet printed sheet from excessive moisture or detrimental environment conditions.

Some protections will also add texture, deeper color, scratch rand graffiti resistance to the final aluminum print.