6 machines for easy access to UV printing

UV 9075 GH, UV1115 GH, UV 1513 GH, UV 1160 GH, UV6045 XII and BeLed

Videos

Faq

Our "standard" range of UV printers has been developed around two main machines : UV5530 + and UV 9075 GH with the aim to offer equipment making access to customization business possible for smaller quantities : customization of phone cases in a store, of pacifiers, of promotional items....

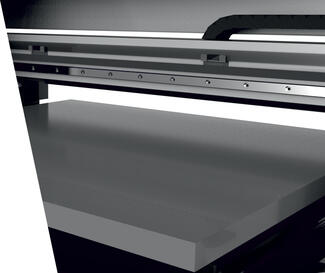

UV printing is fast and direct :

- Product to be printed is positioned on the printing table. For increased productivity, it is possible to make jig / template with places where parts are inserted

- Graphic file with pattern is designed in appropriate CAD software (photoshop, illustrator, coreldraw, ...) and exported in the Rip (Raster Image Processor) special software , replacing driver for print control : faster printing, improved colors, management of printing modes ...

- Pattern is adjusted in terms of size, positioning and printing mode (resolution, drop size ...)

- File is sent for printing : machine is automatically adjusted according to product thickness and printing is carried out.

- Printed product is immediately available and can be unloaded, while the machine goes back

Several techniques can be used for printing objects : pad printing, screen printing, sublimation, offset, ... UV digital printing is one that has many technical advantages and few drawbacks.

Pad printing, screen printing, offset require intermediatel processing steps (production of film, screen, cliché, plate ...) resulting in additional handling and costs that do no exist in UV printing.

Pad printing, screen printing, offset are meant for serial production, not for single part or small series due to the significant cost of screen, cliche... that amortizes on the number of parts. With UV digital printing, no intermediate step is necessary. Printing is direct.

Pad printing, screen printing, ... mainly use inks with solvents that need some time to evaporate. Printed parts cannot be used immediatly. In UV printing, ink is immediately polymerized by a UV LED lamp. Printed products can be used without delay.

UV printing has some limitations:

- It is not possible to print on too convex or concave or irregular surfaces. Print head moving 2 mm above part surface, nothing should obstruct its movement. In case printing part is not perfectly flat, marking accuracy may be impaired when distance between head and printed surface exceeds 4-5 mm

Note: it is however possible to print golf or ping pong balls or pen bodies, reducing their marking surface (example 21-22 mm for golf ball) .

In addition, machines can be equipped with a rotation tool making printing possible on perfect cylinders: wine bottles, gourds, fire extinguishers

- some materials require the application of primer over their surface before printing, so that ink can adhere to the support.

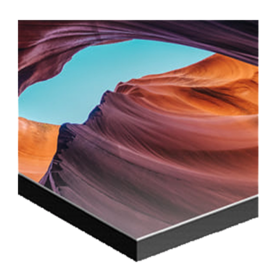

With a UV printer, it is possible to print a multitude of supports: lexan, glass, wood, pmma, aluminum, stainless steel, ... however some of them require a special pre-treatment consisting in applying with a cotton pad, brush, airbrush... a "bonding" primer to make ink adhere on material during UV printing.

We have several primers for different applications.

Since inks do not break when bent, they can be applied both on rigid and flexible items.

Printing speed depends on expected print quality, marking sizes and empty spaces (blank areas are "skipped" by the machine), ink drop size and lamp management mode.

Only tests allow to validate actual output according to desired results. We are at your disposal to carry out tests in our show room.

Printing cost : the machine can be equipped with an optional cost calculator. Before printing, rip software calculates necessary ink amount and quotes marking cost.

Our "standard" range of UV printers has been developed around two main machines : UV5530 + and UV 9075 GH with the aim to offer equipment making access to customization business possible for smaller quantities : customization of phone cases in a store, of pacifiers, of promotional items....

UV printing is fast and direct :

- Product to be printed is positioned on the printing table. For increased productivity, it is possible to make jig / template with places where parts are inserted

- Graphic file with pattern is designed in appropriate CAD software (photoshop, illustrator, coreldraw, ...) and exported in the Rip (Raster Image Processor) special software , replacing driver for print control : faster printing, improved colors, management of printing modes ...

- Pattern is adjusted in terms of size, positioning and printing mode (resolution, drop size ...)

- File is sent for printing : machine is automatically adjusted according to product thickness and printing is carried out.

- Printed product is immediately available and can be unloaded, while the machine goes back

Several techniques can be used for printing objects : pad printing, screen printing, sublimation, offset, ... UV digital printing is one that has many technical advantages and few drawbacks.

Pad printing, screen printing, offset require intermediatel processing steps (production of film, screen, cliché, plate ...) resulting in additional handling and costs that do no exist in UV printing.

Pad printing, screen printing, offset are meant for serial production, not for single part or small series due to the significant cost of screen, cliche... that amortizes on the number of parts. With UV digital printing, no intermediate step is necessary. Printing is direct.

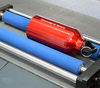

Pad printing, screen printing, ... mainly use inks with solvents that need some time to evaporate. Printed parts cannot be used immediatly. In UV printing, ink is immediately polymerized by a UV LED lamp. Printed products can be used without delay.

UV printing has some limitations:

- It is not possible to print on too convex or concave or irregular surfaces. Print head moving 2 mm above part surface, nothing should obstruct its movement. In case printing part is not perfectly flat, marking accuracy may be impaired when distance between head and printed surface exceeds 4-5 mm

Note: it is however possible to print golf or ping pong balls or pen bodies, reducing their marking surface (example 21-22 mm for golf ball) .

In addition, machines can be equipped with a rotation tool making printing possible on perfect cylinders: wine bottles, gourds, fire extinguishers

- some materials require the application of primer over their surface before printing, so that ink can adhere to the support.

With a UV printer, it is possible to print a multitude of supports: lexan, glass, wood, pmma, aluminum, stainless steel, ... however some of them require a special pre-treatment consisting in applying with a cotton pad, brush, airbrush... a "bonding" primer to make ink adhere on material during UV printing.

We have several primers for different applications.

Since inks do not break when bent, they can be applied both on rigid and flexible items.

Printing speed depends on expected print quality, marking sizes and empty spaces (blank areas are "skipped" by the machine), ink drop size and lamp management mode.

Only tests allow to validate actual output according to desired results. We are at your disposal to carry out tests in our show room.

Printing cost : the machine can be equipped with an optional cost calculator. Before printing, rip software calculates necessary ink amount and quotes marking cost.

Our "standard" range of UV printers has been developed around two main machines : UV5530 + and UV 9075 GH with the aim to offer equipment making access to customization business possible for smaller quantities : customization of phone cases in a store, of pacifiers, of promotional items....

UV printing is fast and direct :

- Product to be printed is positioned on the printing table. For increased productivity, it is possible to make jig / template with places where parts are inserted

- Graphic file with pattern is designed in appropriate CAD software (photoshop, illustrator, coreldraw, ...) and exported in the Rip (Raster Image Processor) special software , replacing driver for print control : faster printing, improved colors, management of printing modes ...

- Pattern is adjusted in terms of size, positioning and printing mode (resolution, drop size ...)

- File is sent for printing : machine is automatically adjusted according to product thickness and printing is carried out.

- Printed product is immediately available and can be unloaded, while the machine goes back

Several techniques can be used for printing objects : pad printing, screen printing, sublimation, offset, ... UV digital printing is one that has many technical advantages and few drawbacks.

Pad printing, screen printing, offset require intermediatel processing steps (production of film, screen, cliché, plate ...) resulting in additional handling and costs that do no exist in UV printing.

Pad printing, screen printing, offset are meant for serial production, not for single part or small series due to the significant cost of screen, cliche... that amortizes on the number of parts. With UV digital printing, no intermediate step is necessary. Printing is direct.

Pad printing, screen printing, ... mainly use inks with solvents that need some time to evaporate. Printed parts cannot be used immediatly. In UV printing, ink is immediately polymerized by a UV LED lamp. Printed products can be used without delay.

UV printing has some limitations:

- It is not possible to print on too convex or concave or irregular surfaces. Print head moving 2 mm above part surface, nothing should obstruct its movement. In case printing part is not perfectly flat, marking accuracy may be impaired when distance between head and printed surface exceeds 4-5 mm

Note: it is however possible to print golf or ping pong balls or pen bodies, reducing their marking surface (example 21-22 mm for golf ball) .

In addition, machines can be equipped with a rotation tool making printing possible on perfect cylinders: wine bottles, gourds, fire extinguishers

- some materials require the application of primer over their surface before printing, so that ink can adhere to the support.

With a UV printer, it is possible to print a multitude of supports: lexan, glass, wood, pmma, aluminum, stainless steel, ... however some of them require a special pre-treatment consisting in applying with a cotton pad, brush, airbrush... a "bonding" primer to make ink adhere on material during UV printing.

We have several primers for different applications.

Since inks do not break when bent, they can be applied both on rigid and flexible items.

Printing speed depends on expected print quality, marking sizes and empty spaces (blank areas are "skipped" by the machine), ink drop size and lamp management mode.

Only tests allow to validate actual output according to desired results. We are at your disposal to carry out tests in our show room.

Printing cost : the machine can be equipped with an optional cost calculator. Before printing, rip software calculates necessary ink amount and quotes marking cost.

Our "standard" range of UV printers has been developed around two main machines : UV5530 + and UV 9075 GH with the aim to offer equipment making access to customization business possible for smaller quantities : customization of phone cases in a store, of pacifiers, of promotional items....

UV printing is fast and direct :

- Product to be printed is positioned on the printing table. For increased productivity, it is possible to make jig / template with places where parts are inserted

- Graphic file with pattern is designed in appropriate CAD software (photoshop, illustrator, coreldraw, ...) and exported in the Rip (Raster Image Processor) special software , replacing driver for print control : faster printing, improved colors, management of printing modes ...

- Pattern is adjusted in terms of size, positioning and printing mode (resolution, drop size ...)

- File is sent for printing : machine is automatically adjusted according to product thickness and printing is carried out.

- Printed product is immediately available and can be unloaded, while the machine goes back

Several techniques can be used for printing objects : pad printing, screen printing, sublimation, offset, ... UV digital printing is one that has many technical advantages and few drawbacks.

Pad printing, screen printing, offset require intermediatel processing steps (production of film, screen, cliché, plate ...) resulting in additional handling and costs that do no exist in UV printing.

Pad printing, screen printing, offset are meant for serial production, not for single part or small series due to the significant cost of screen, cliche... that amortizes on the number of parts. With UV digital printing, no intermediate step is necessary. Printing is direct.

Pad printing, screen printing, ... mainly use inks with solvents that need some time to evaporate. Printed parts cannot be used immediatly. In UV printing, ink is immediately polymerized by a UV LED lamp. Printed products can be used without delay.

UV printing has some limitations:

- It is not possible to print on too convex or concave or irregular surfaces. Print head moving 2 mm above part surface, nothing should obstruct its movement. In case printing part is not perfectly flat, marking accuracy may be impaired when distance between head and printed surface exceeds 4-5 mm

Note: it is however possible to print golf or ping pong balls or pen bodies, reducing their marking surface (example 21-22 mm for golf ball) .

In addition, machines can be equipped with a rotation tool making printing possible on perfect cylinders: wine bottles, gourds, fire extinguishers

- some materials require the application of primer over their surface before printing, so that ink can adhere to the support.

With a UV printer, it is possible to print a multitude of supports: lexan, glass, wood, pmma, aluminum, stainless steel, ... however some of them require a special pre-treatment consisting in applying with a cotton pad, brush, airbrush... a "bonding" primer to make ink adhere on material during UV printing.

We have several primers for different applications.

Since inks do not break when bent, they can be applied both on rigid and flexible items.

Printing speed depends on expected print quality, marking sizes and empty spaces (blank areas are "skipped" by the machine), ink drop size and lamp management mode.

Only tests allow to validate actual output according to desired results. We are at your disposal to carry out tests in our show room.

Printing cost : the machine can be equipped with an optional cost calculator. Before printing, rip software calculates necessary ink amount and quotes marking cost.

Our "standard" range of UV printers has been developed around two main machines : UV5530 + and UV 9075 GH with the aim to offer equipment making access to customization business possible for smaller quantities : customization of phone cases in a store, of pacifiers, of promotional items....

UV printing is fast and direct :

- Product to be printed is positioned on the printing table. For increased productivity, it is possible to make jig / template with places where parts are inserted

- Graphic file with pattern is designed in appropriate CAD software (photoshop, illustrator, coreldraw, ...) and exported in the Rip (Raster Image Processor) special software , replacing driver for print control : faster printing, improved colors, management of printing modes ...

- Pattern is adjusted in terms of size, positioning and printing mode (resolution, drop size ...)

- File is sent for printing : machine is automatically adjusted according to product thickness and printing is carried out.

- Printed product is immediately available and can be unloaded, while the machine goes back

Several techniques can be used for printing objects : pad printing, screen printing, sublimation, offset, ... UV digital printing is one that has many technical advantages and few drawbacks.

Pad printing, screen printing, offset require intermediatel processing steps (production of film, screen, cliché, plate ...) resulting in additional handling and costs that do no exist in UV printing.

Pad printing, screen printing, offset are meant for serial production, not for single part or small series due to the significant cost of screen, cliche... that amortizes on the number of parts. With UV digital printing, no intermediate step is necessary. Printing is direct.

Pad printing, screen printing, ... mainly use inks with solvents that need some time to evaporate. Printed parts cannot be used immediatly. In UV printing, ink is immediately polymerized by a UV LED lamp. Printed products can be used without delay.

UV printing has some limitations:

- It is not possible to print on too convex or concave or irregular surfaces. Print head moving 2 mm above part surface, nothing should obstruct its movement. In case printing part is not perfectly flat, marking accuracy may be impaired when distance between head and printed surface exceeds 4-5 mm

Note: it is however possible to print golf or ping pong balls or pen bodies, reducing their marking surface (example 21-22 mm for golf ball) .

In addition, machines can be equipped with a rotation tool making printing possible on perfect cylinders: wine bottles, gourds, fire extinguishers

- some materials require the application of primer over their surface before printing, so that ink can adhere to the support.

With a UV printer, it is possible to print a multitude of supports: lexan, glass, wood, pmma, aluminum, stainless steel, ... however some of them require a special pre-treatment consisting in applying with a cotton pad, brush, airbrush... a "bonding" primer to make ink adhere on material during UV printing.

We have several primers for different applications.

Since inks do not break when bent, they can be applied both on rigid and flexible items.

Printing speed depends on expected print quality, marking sizes and empty spaces (blank areas are "skipped" by the machine), ink drop size and lamp management mode.

Only tests allow to validate actual output according to desired results. We are at your disposal to carry out tests in our show room.

Printing cost : the machine can be equipped with an optional cost calculator. Before printing, rip software calculates necessary ink amount and quotes marking cost.

Our "standard" range of UV printers has been developed around two main machines : UV5530 + and UV 9075 GH with the aim to offer equipment making access to customization business possible for smaller quantities : customization of phone cases in a store, of pacifiers, of promotional items....

UV printing is fast and direct :

- Product to be printed is positioned on the printing table. For increased productivity, it is possible to make jig / template with places where parts are inserted

- Graphic file with pattern is designed in appropriate CAD software (photoshop, illustrator, coreldraw, ...) and exported in the Rip (Raster Image Processor) special software , replacing driver for print control : faster printing, improved colors, management of printing modes ...

- Pattern is adjusted in terms of size, positioning and printing mode (resolution, drop size ...)

- File is sent for printing : machine is automatically adjusted according to product thickness and printing is carried out.

- Printed product is immediately available and can be unloaded, while the machine goes back

Several techniques can be used for printing objects : pad printing, screen printing, sublimation, offset, ... UV digital printing is one that has many technical advantages and few drawbacks.

Pad printing, screen printing, offset require intermediatel processing steps (production of film, screen, cliché, plate ...) resulting in additional handling and costs that do no exist in UV printing.

Pad printing, screen printing, offset are meant for serial production, not for single part or small series due to the significant cost of screen, cliche... that amortizes on the number of parts. With UV digital printing, no intermediate step is necessary. Printing is direct.

Pad printing, screen printing, ... mainly use inks with solvents that need some time to evaporate. Printed parts cannot be used immediatly. In UV printing, ink is immediately polymerized by a UV LED lamp. Printed products can be used without delay.

UV printing has some limitations:

- It is not possible to print on too convex or concave or irregular surfaces. Print head moving 2 mm above part surface, nothing should obstruct its movement. In case printing part is not perfectly flat, marking accuracy may be impaired when distance between head and printed surface exceeds 4-5 mm

Note: it is however possible to print golf or ping pong balls or pen bodies, reducing their marking surface (example 21-22 mm for golf ball) .

In addition, machines can be equipped with a rotation tool making printing possible on perfect cylinders: wine bottles, gourds, fire extinguishers

- some materials require the application of primer over their surface before printing, so that ink can adhere to the support.

With a UV printer, it is possible to print a multitude of supports: lexan, glass, wood, pmma, aluminum, stainless steel, ... however some of them require a special pre-treatment consisting in applying with a cotton pad, brush, airbrush... a "bonding" primer to make ink adhere on material during UV printing.

We have several primers for different applications.

Since inks do not break when bent, they can be applied both on rigid and flexible items.

Printing speed depends on expected print quality, marking sizes and empty spaces (blank areas are "skipped" by the machine), ink drop size and lamp management mode.

Only tests allow to validate actual output according to desired results. We are at your disposal to carry out tests in our show room.

Printing cost : the machine can be equipped with an optional cost calculator. Before printing, rip software calculates necessary ink amount and quotes marking cost.

The Beled UV machine has the advantage of having as standard a very high printing height (300 mm) and a high printing speed compared to printers equipped with a more graphic head.