Products and equipment for photopolymer stamp making

designed or marketed by our company for over 60 years

Materials and supplies needed

Thermogravor photopolymer processing machine

A 4 size photopolymer processing machine

Designed and manufactured by our company, to produce photopolymer stamps from liquid resin or hard photopolymer plates to be pressed into a matrix board (mold)

The machine is made of 3 parts :

Exposure part (to expose photopolymer material to UV light)

- UV tubes with on/off digital timer including memory

- vacuum pump to keep positive and negative films or negative film and photopolymer plate in close contact

- glasses with closing and calibrating system for liquid photoplymer material processing

- plastic tray with holding system, for liquid resin post exposure

- compressor to pierce air bubbles in liquid resin

Engraving part : (to develop (wash out) photopolymer material

- all pieces are in stainless steel

- thermostat for water temperature control

- timer to start the engraving unit

- the engraving mechanism is outside water to avoid dirt and jamming problems of the moving part

Drying part (to harden photopolymer material)

- 3 drying compartments

- temperature control by thermostat

- on/off timer

- 3 drying compartments

Applications

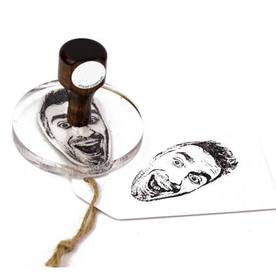

Company Logo, slogan, picto... reproduction with a photopolymer stamp

Transparent mount with a clear stamp : for easy to printing positioning

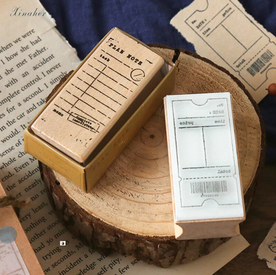

Company stamp : contact details, accounting, store, ... in photopolymer resin

Company stamps with name, address, registration number... in photoplymer stamp

Easy print positioning with photopolymer stamp assembled on a transparent block

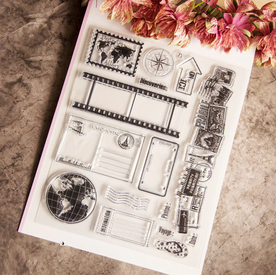

Sheet of clear stamps for decoration: card making, scrapbooking, announcement ...

Photopolymer stamp on wooden mount : a vintage look for your decorations

When printing your decoration, clear resin makes print positioning easier

Your creations of announcements, scrapbooking, card making, home decor or any other creative ideas with photopolymer stamps

Customize your creations with a photopolypmer stamp

Clear photopolymer stamp for creative hobbies: birthday cards, greetings, menus ...

Greeting cards, menus, announcements... illustrated with photopolymer stamps

Clear stamp on transparent mount for scrapbooking

Clear photopolymer stamp for your company

Clear photopolymer for company stamp

Clear stamp for decoration of menu cards, announcements...

Scrapbooking with clear photopolymer stamps

Photopolymer stamp for company logos

Videos

Faq

« stamp » word can include inking pad, box containing ink pad, instrument used to transfer a print on a document and even final print. Stamp can be manual or automatic.

Our company offers products for the “seal” technical part of the stamp : part in rubber, photopolymer or pre inked material with characters, logo or drawing to print.

In case of rubber or photopolymer resin, stamp surface should be coated with ink from an ink pad. Then, stamp is placed above support and pressure is applied to transfer ink from stamp surface to the support. For another print, it is necessary to ink again stamp surface.

In case of pre-inked material, ink is directly contained in the microporous structure of the stamp (ink capsules).

Rubber stamps are mainly used for administrative applications, as a signature of a company, administration, commercial entity or individual. However other kind of stamps are available, such as daters specifically used to date documents or numberers to affix numbers on document series.

In France, company stamp is required to process most documents such as contracts, quotes or delivery notes. Signature is generally made next to or on the company stamp, with date.

Stamp is also widely used in scrapbooking applications, to customize creations : cards, announcements, albums, Christmas cards, birthdays… Multiple accessories are available for using rubber stamps in a different way : embossing powder, multi-color ink, metallic inks ...

Finally, stamps are also used in specific applications: outdoor use with UV inks, tracking information (for instance ampoules, with acid inks), textile marking for clothes…

Historically, texts were arranged and images were engraved by typographic workers then gathered together and tightened inside a forme. Then a matrix made of wax and other materials was placed on top and the whole was placed inside a heating press to imprim patterns inside softened wax.

After cooling, the wax mold was covered with rubber and parchment paper and placed again in the heating press so that rubber can flow inside mold depth and produce relief for stamps. The resulting rubber sheet was cut into stamps.

Development of computers allowed to give up cumbersome manufacturing tools (lead character fonts, presses..) and use computer-aided publication and photosensitive polymers

Now, stamp manufacturing process consists of several easy steps:

- patterns to be reproduced are drawn on a computer

- a film is printed to get a negative

- photopolymer liquid resin is exposed through the negative to get a photopolymer stamp, or hard photopolymer plate is exposed to produce a cliche

- photopolymer cliche is pressed into a matrix board to get a mold for rubber (rubber stamps) or premix gel (pre inked stamps) moulding

In case of rubber stamps, two manufacturing solutions are possible : laser engraved rubber or rubber molded in a matrix board. These two techniques are to be compared to photopolymer resin technique

Photopolymer liquid advantages

- faster processing (25 -30 minutes).

- a single small sized machine necessary

- very low equipment depreciation therefore low stamp cost price

Photopolymer liquid drawbacks

- ink restitution not so good (polymer closed structure)

- resistance not so good over time

- resistance to alcohol-based inks not so good

Laser/conventional rubber advantages

- better resistance to inks (especially alcohol-based ones).

- more resistant over time

- better ink restitution (rubber por

- choice of colors, nobler material.

Laser engraved rubber advantages

- Fast processing (3 minutes 30 s) for a single stamp with a laser engraver

Conventional rubber advantages

- lower equipment cost, compared to laser

- Cost for additional copies of a same stamp is very low and processing very fast : once the mold (with patterns in hollow) is obtained, only rubber is necessary and fast vulcanized.

Laser engraved rubber drawbacks

- high investment cost (laser engraver)

- long engraving time (2 hours 40 for A4 size, including 40 stamps, with a 30 w machine) that can be reduced using a higher power laser tube.

- important maintenance : 90 % of rubber material need to be removed and release a lot of dust that dirty the machine.

- same work and same cost for additional copies of a same stamp

Conventional rubber drawbacks :

- longer processing time for the first copy (1 hour 10 for a 40 stamp A4 size)

Production of photopolymer stamps is very easy and does not require important equipment.

Once a positive film is printed (laser or inkjet printer), all other operations are made in the same Thermogravor machine including 3 parts: exposure, engraving, drying.

Negative film is processed in the exposure part of the machine, then developed and fixed in trays

Liquid resin is

- exposed in the exposure part of the machine

- washed out in the engraving part of the machine

- post exposed in the exposure part of the machine

- dried in the drying part of the machine.

Space-saving, easy to use and designed by Thermoflan, Thermogravor machine allows the manufacture of photopolymer stamps up to A4 format.

Characteristics of 3 stamp types are summarized in the table below:

As a result:

Photopolymer stamps require low investment; their production is relatively economical and fast.

Conventional rubber stamps are interesting for large volume and additional copies of a same stamp (scrapbooking for instance)

Laser speed is interesting for small quantities, larger quantities requiring significant investment (100 w power). Also, it is important not to forget laser maintenance cost.

Thermoflex 50 v resin: with the help of ANVAR (French agency for research valuation) and National School of Chemistry of Montpellier, we have developed a photopolymer resin for direct stamp production. Available in different hardnesses, our resin has a quality / price advantage never offered in stamp making

Advantages of our resin are :

Working conditions :

Thermoflex 50 V does not require the St Andrew’s cross on the label. This simply means that this is a much safer product to work with.

Odor :

Thermoflex 50 V is an odourless liquid photopolymer.

Engraving / Water washable :

Thermoflex 50 V can be easily washed out with compatible wash out detergent solution.

Adhesion :Thermoflex 50 V adheres well to the backing film.

Tackfree :

Thermoflex 50 V has no tackiness

Ink transfer and image definition:

Elasticity of the polymer improves the image definition. Thermoflex 50 V is more elastic and can produce sharp, clear prints.

Longer life :

Due to proper hardness and flexibility, photopolymer plate has a longer press life and the plates have a higher resistance to abrasion

Wick effect :

Unlike most resins on the market, Thermoflex 50 V resin does not absorb aqueous parts of ink. As a result there is no risk for ink pads to dry faster then expected.

Resistance to UV light :

UV does not alter Thermoflex 50 V resin

Appearence :

Thermoflex 50 V is a green, transparent photopolymer material