Mark, engrave, track

your products with our fiber lasers

Applications

Customization of promotional gifts with a fiber laser: metals and plastics

Metal engraving in medical industry : identification in accordance with strict directives

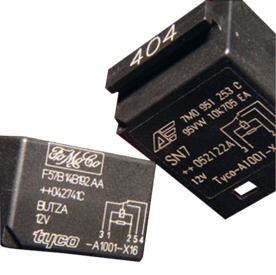

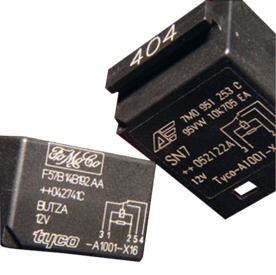

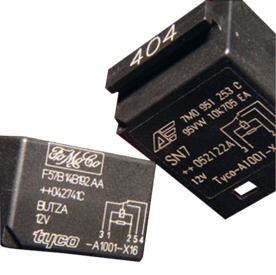

Electronic industry, plastic industry : high contrast marking on plastics with a fiber laser.

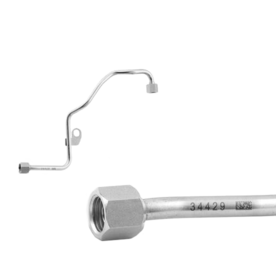

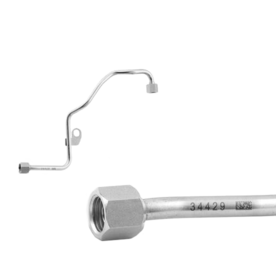

Manufacturing date, serial number ... marked on metal with a fiber laser machine

Inside / outside jewel engraving for jewelry

Engraving of nameplates : stainless steel, aluminum, brass, ... with a fiber laser.

High contrast marking on plastics with fiber lasers : manufacturing date, batch number, dynamic contents ...

Metal cutting: gold, silver, brass ... with a fiber laser: jewelry, fantasy, design, fashion ...

Fiber laser marking on plastic parts: logistics, traceability, increments, ...

Applications

Customization of promotional gifts with a fiber laser: metals and plastics

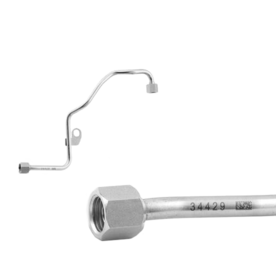

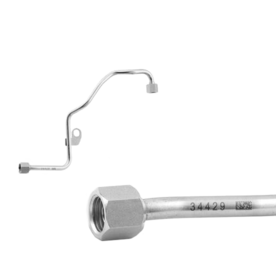

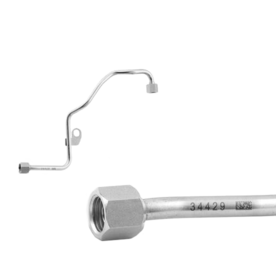

Metal engraving in medical industry : identification in accordance with strict directives

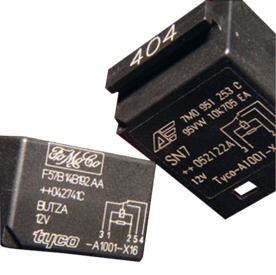

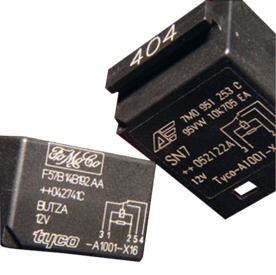

Electronic industry, plastic industry : high contrast marking on plastics with a fiber laser.

Manufacturing date, serial number ... marked on metal with a fiber laser machine

Inside / outside jewel engraving for jewelry

Engraving of nameplates : stainless steel, aluminum, brass, ... with a fiber laser.

High contrast marking on plastics with fiber lasers : manufacturing date, batch number, dynamic contents ...

Metal cutting: gold, silver, brass ... with a fiber laser: jewelry, fantasy, design, fashion ...

Fiber laser marking on plastic parts: logistics, traceability, increments, ...

Applications

Customization of promotional gifts with a fiber laser: metals and plastics

Metal engraving in medical industry : identification in accordance with strict directives

Electronic industry, plastic industry : high contrast marking on plastics with a fiber laser.

Manufacturing date, serial number ... marked on metal with a fiber laser machine

Inside / outside jewel engraving for jewelry

Engraving of nameplates : stainless steel, aluminum, brass, ... with a fiber laser.

High contrast marking on plastics with fiber lasers : manufacturing date, batch number, dynamic contents ...

Metal cutting: gold, silver, brass ... with a fiber laser: jewelry, fantasy, design, fashion ...

Fiber laser marking on plastic parts: logistics, traceability, increments, ...

Applications

Customization of promotional gifts with a fiber laser: metals and plastics

Metal engraving in medical industry : identification in accordance with strict directives

Electronic industry, plastic industry : high contrast marking on plastics with a fiber laser.

Manufacturing date, serial number ... marked on metal with a fiber laser machine

Inside / outside jewel engraving for jewelry

Engraving of nameplates : stainless steel, aluminum, brass, ... with a fiber laser.

High contrast marking on plastics with fiber lasers : manufacturing date, batch number, dynamic contents ...

Metal cutting: gold, silver, brass ... with a fiber laser: jewelry, fantasy, design, fashion ...

Fiber laser marking on plastic parts: logistics, traceability, increments, ...

Applications

Customization of promotional gifts with a fiber laser: metals and plastics

Metal engraving in medical industry : identification in accordance with strict directives

Electronic industry, plastic industry : high contrast marking on plastics with a fiber laser.

Manufacturing date, serial number ... marked on metal with a fiber laser machine

Inside / outside jewel engraving for jewelry

Engraving of nameplates : stainless steel, aluminum, brass, ... with a fiber laser.

High contrast marking on plastics with fiber lasers : manufacturing date, batch number, dynamic contents ...

Metal cutting: gold, silver, brass ... with a fiber laser: jewelry, fantasy, design, fashion ...

Fiber laser marking on plastic parts: logistics, traceability, increments, ...

Videos

Documentation

Download

Faq

The two technologies are different in terms of wavelength (Fiber = 1.064 and Co2 = 10.64 micrometers).

Wavelength being more or less absorbed according to materials, laser source should be selected according to material nature and desired application (marking / engraving / cutting)

CO2 source

Marking: wood, paper, cardboard, leather, textile, ceramic, cork, anodized aluminum, lacquered metals.

Engraving: Wood, glass, paper, cardboard, leather, textile, mirror, stone, cork, lacquered metals, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam

Cutting: Wood, paper, cardboard, leather, textile, cork, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam.

Fiber Source

Marking: colored paper, leather, textile, ceramic, aluminum, anodized aluminum, precious metals, Steel, brass, copper, titanium, stainless steel, PA, PBT, PC, PE, PES, PET, PE, PP, PS, PUR, Foam

Engraving: Mirror, Ceramic, aluminum, anodized aluminum, lacquered metals, precious metals, Steel, brass, copper, titanium, stainless steel.

Cutting: fine metals up to 0.5 mm

Wavelength of fiber lasers is 1,064 micrometers, with a very small beam diameter and a much higher power than a same power Co2 machine (about 100 times greater).

They are used for metal marking and engraving : stainless steel, silver, gold, brass, titanium ... and for high contrast marking on plastics but also on leather, textiles and paper.

They can also be used in thin metal cutting, for instance in for jewelery business : gold, silver,etc

Depending on processed material and application (engraving, marking or cutting), power should be adapted.

For plastic or metal marking applications, low power is necessary.

For engraving or cutting applications, higher power is advised.

Our technical department can make tests and determine the most suitable equipement for your products.

Our machine range is available in different powers and working surfaces:

- power from 20 to 50 w

- working sizes from 70 x 70 mm to 1000 x 500 mm

and different technologies depending on required productivity and automation level :

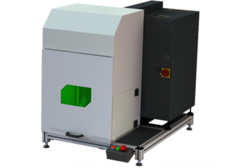

- OEM integrable in production lines

- Fiber mark Pro 3 in stand alone working station

- Pendulum fiber mark for a first level of automation

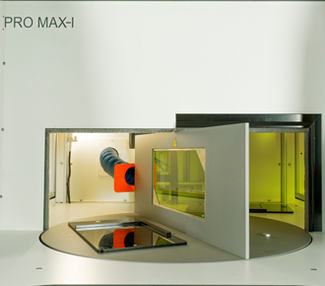

- Fiber Mark Pro Max I with indexed turn table

- Fiber Max Pro Max XY for a large marking surface.

Our range flexibility will allow us to find the right version complying with your specifications.

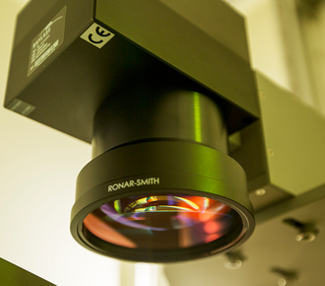

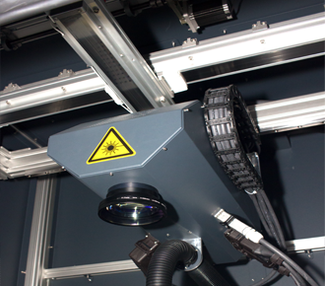

All our fiber lasers are equipped with galvanometric heads for beam guidage.

The head is "waterproof" and maintenance is almost non-existent. The only output lens should be cleaned regularly, but since it is located far from processed materiel, it does not get very dirty.

Expected life of laser source is several years (MTBM 100,000 hours).

Our lasers are safe for the operator.

There are several laser classes

- class 1: Lasers that are safe when used, even for direct vision of the beam over a long period and even when using telescopic optical devices.

- class 2: Lasers emitting from 400 nm to 700 nm wavelength visible radiation, harmless for temporary exposures (0.25 s), but harmful in case deliberate vision of the beam.

- class 3: Lasers emitting radiation which may exceed the EMP in case of direct vision of the beam, but with relatively low risk of injury in most cases. We do not have this type of laser.

- class 4: Lasers for which vision in the beam and skin exposure are dangerous.Also, vision of diffuse reflections can be dangerous. A fire hazard is also often present with this kind of laser. They require wearing protective glasses.

Our lasers belong to the 2nd class as they are equipped as standard with a red dot pointer allowing to simulate work or start it at a determined place. The red dot pointer power being very low (less than one mw), it is not dangerous.

All our machines comply with CE standards and meet requirements of Machinery Directive 2006/42 / EC.

They are supplied with:

- a key switch to start the tube

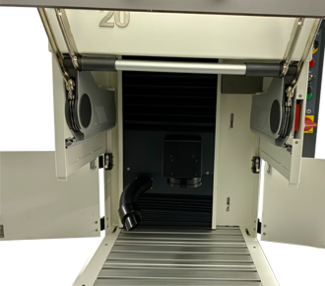

- door safety systems immediatly stopping laser emission in case the laser compartment is opened.

- an easily accessible emergency stop button.

- a special safety window for absorption of the laser beam.

The two technologies are different in terms of wavelength (Fiber = 1.064 and Co2 = 10.64 micrometers).

Wavelength being more or less absorbed according to materials, laser source should be selected according to material nature and desired application (marking / engraving / cutting)

CO2 source

Marking: wood, paper, cardboard, leather, textile, ceramic, cork, anodized aluminum, lacquered metals.

Engraving: Wood, glass, paper, cardboard, leather, textile, mirror, stone, cork, lacquered metals, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam

Cutting: Wood, paper, cardboard, leather, textile, cork, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam.

Fiber Source

Marking: colored paper, leather, textile, ceramic, aluminum, anodized aluminum, precious metals, Steel, brass, copper, titanium, stainless steel, PA, PBT, PC, PE, PES, PET, PE, PP, PS, PUR, Foam

Engraving: Mirror, Ceramic, aluminum, anodized aluminum, lacquered metals, precious metals, Steel, brass, copper, titanium, stainless steel.

Cutting: fine metals up to 0.5 mm

Wavelength of fiber lasers is 1,064 micrometers, with a very small beam diameter and a much higher power than a same power Co2 machine (about 100 times greater).

They are used for metal marking and engraving : stainless steel, silver, gold, brass, titanium ... and for high contrast marking on plastics but also on leather, textiles and paper.

They can also be used in thin metal cutting, for instance in for jewelery business : gold, silver,etc

Depending on processed material and application (engraving, marking or cutting), power should be adapted.

For plastic or metal marking applications, low power is necessary.

For engraving or cutting applications, higher power is advised.

Our technical department can make tests and determine the most suitable equipement for your products.

Our machine range is available in different powers and working surfaces:

- power from 20 to 50 w

- working sizes from 70 x 70 mm to 1000 x 500 mm

and different technologies depending on required productivity and automation level :

- OEM integrable in production lines

- Fiber mark Pro 3 in stand alone working station

- Pendulum fiber mark for a first level of automation

- Fiber Mark Pro Max I with indexed turn table

- Fiber Max Pro Max XY for a large marking surface.

Our range flexibility will allow us to find the right version complying with your specifications.

All our fiber lasers are equipped with galvanometric heads for beam guidage.

The head is "waterproof" and maintenance is almost non-existent. The only output lens should be cleaned regularly, but since it is located far from processed materiel, it does not get very dirty.

Expected life of laser source is several years (MTBM 100,000 hours).

Our lasers are safe for the operator.

There are several laser classes

- class 1: Lasers that are safe when used, even for direct vision of the beam over a long period and even when using telescopic optical devices.

- class 2: Lasers emitting from 400 nm to 700 nm wavelength visible radiation, harmless for temporary exposures (0.25 s), but harmful in case deliberate vision of the beam.

- class 3: Lasers emitting radiation which may exceed the EMP in case of direct vision of the beam, but with relatively low risk of injury in most cases. We do not have this type of laser.

- class 4: Lasers for which vision in the beam and skin exposure are dangerous.Also, vision of diffuse reflections can be dangerous. A fire hazard is also often present with this kind of laser. They require wearing protective glasses.

Our lasers belong to the 2nd class as they are equipped as standard with a red dot pointer allowing to simulate work or start it at a determined place. The red dot pointer power being very low (less than one mw), it is not dangerous.

All our machines comply with CE standards and meet requirements of Machinery Directive 2006/42 / EC.

They are supplied with:

- a key switch to start the tube

- door safety systems immediatly stopping laser emission in case the laser compartment is opened.

- an easily accessible emergency stop button.

- a special safety window for absorption of the laser beam.

The two technologies are different in terms of wavelength (Fiber = 1.064 and Co2 = 10.64 micrometers).

Wavelength being more or less absorbed according to materials, laser source should be selected according to material nature and desired application (marking / engraving / cutting)

CO2 source

Marking: wood, paper, cardboard, leather, textile, ceramic, cork, anodized aluminum, lacquered metals.

Engraving: Wood, glass, paper, cardboard, leather, textile, mirror, stone, cork, lacquered metals, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam

Cutting: Wood, paper, cardboard, leather, textile, cork, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam.

Fiber Source

Marking: colored paper, leather, textile, ceramic, aluminum, anodized aluminum, precious metals, Steel, brass, copper, titanium, stainless steel, PA, PBT, PC, PE, PES, PET, PE, PP, PS, PUR, Foam

Engraving: Mirror, Ceramic, aluminum, anodized aluminum, lacquered metals, precious metals, Steel, brass, copper, titanium, stainless steel.

Cutting: fine metals up to 0.5 mm

Wavelength of fiber lasers is 1,064 micrometers, with a very small beam diameter and a much higher power than a same power Co2 machine (about 100 times greater).

They are used for metal marking and engraving : stainless steel, silver, gold, brass, titanium ... and for high contrast marking on plastics but also on leather, textiles and paper.

They can also be used in thin metal cutting, for instance in for jewelery business : gold, silver,etc

Depending on processed material and application (engraving, marking or cutting), power should be adapted.

For plastic or metal marking applications, low power is necessary.

For engraving or cutting applications, higher power is advised.

Our technical department can make tests and determine the most suitable equipement for your products.

Our machine range is available in different powers and working surfaces:

- power from 20 to 50 w

- working sizes from 70 x 70 mm to 1000 x 500 mm

and different technologies depending on required productivity and automation level :

- OEM integrable in production lines

- Fiber mark Pro 3 in stand alone working station

- Pendulum fiber mark for a first level of automation

- Fiber Mark Pro Max I with indexed turn table

- Fiber Max Pro Max XY for a large marking surface.

Our range flexibility will allow us to find the right version complying with your specifications.

All our fiber lasers are equipped with galvanometric heads for beam guidage.

The head is "waterproof" and maintenance is almost non-existent. The only output lens should be cleaned regularly, but since it is located far from processed materiel, it does not get very dirty.

Expected life of laser source is several years (MTBM 100,000 hours).

Our lasers are safe for the operator.

There are several laser classes

- class 1: Lasers that are safe when used, even for direct vision of the beam over a long period and even when using telescopic optical devices.

- class 2: Lasers emitting from 400 nm to 700 nm wavelength visible radiation, harmless for temporary exposures (0.25 s), but harmful in case deliberate vision of the beam.

- class 3: Lasers emitting radiation which may exceed the EMP in case of direct vision of the beam, but with relatively low risk of injury in most cases. We do not have this type of laser.

- class 4: Lasers for which vision in the beam and skin exposure are dangerous.Also, vision of diffuse reflections can be dangerous. A fire hazard is also often present with this kind of laser. They require wearing protective glasses.

Our lasers belong to the 2nd class as they are equipped as standard with a red dot pointer allowing to simulate work or start it at a determined place. The red dot pointer power being very low (less than one mw), it is not dangerous.

All our machines comply with CE standards and meet requirements of Machinery Directive 2006/42 / EC.

They are supplied with:

- a key switch to start the tube

- door safety systems immediatly stopping laser emission in case the laser compartment is opened.

- an easily accessible emergency stop button.

- a special safety window for absorption of the laser beam.

The two technologies are different in terms of wavelength (Fiber = 1.064 and Co2 = 10.64 micrometers).

Wavelength being more or less absorbed according to materials, laser source should be selected according to material nature and desired application (marking / engraving / cutting)

CO2 source

Marking: wood, paper, cardboard, leather, textile, ceramic, cork, anodized aluminum, lacquered metals.

Engraving: Wood, glass, paper, cardboard, leather, textile, mirror, stone, cork, lacquered metals, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam

Cutting: Wood, paper, cardboard, leather, textile, cork, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam.

Fiber Source

Marking: colored paper, leather, textile, ceramic, aluminum, anodized aluminum, precious metals, Steel, brass, copper, titanium, stainless steel, PA, PBT, PC, PE, PES, PET, PE, PP, PS, PUR, Foam

Engraving: Mirror, Ceramic, aluminum, anodized aluminum, lacquered metals, precious metals, Steel, brass, copper, titanium, stainless steel.

Cutting: fine metals up to 0.5 mm

Wavelength of fiber lasers is 1,064 micrometers, with a very small beam diameter and a much higher power than a same power Co2 machine (about 100 times greater).

They are used for metal marking and engraving : stainless steel, silver, gold, brass, titanium ... and for high contrast marking on plastics but also on leather, textiles and paper.

They can also be used in thin metal cutting, for instance in for jewelery business : gold, silver,etc

Depending on processed material and application (engraving, marking or cutting), power should be adapted.

For plastic or metal marking applications, low power is necessary.

For engraving or cutting applications, higher power is advised.

Our technical department can make tests and determine the most suitable equipement for your products.

Our machine range is available in different powers and working surfaces:

- power from 20 to 50 w

- working sizes from 70 x 70 mm to 1000 x 500 mm

and different technologies depending on required productivity and automation level :

- OEM integrable in production lines

- Fiber mark Pro 3 in stand alone working station

- Pendulum fiber mark for a first level of automation

- Fiber Mark Pro Max I with indexed turn table

- Fiber Max Pro Max XY for a large marking surface.

Our range flexibility will allow us to find the right version complying with your specifications.

All our fiber lasers are equipped with galvanometric heads for beam guidage.

The head is "waterproof" and maintenance is almost non-existent. The only output lens should be cleaned regularly, but since it is located far from processed materiel, it does not get very dirty.

Expected life of laser source is several years (MTBM 100,000 hours).

Our lasers are safe for the operator.

There are several laser classes

- class 1: Lasers that are safe when used, even for direct vision of the beam over a long period and even when using telescopic optical devices.

- class 2: Lasers emitting from 400 nm to 700 nm wavelength visible radiation, harmless for temporary exposures (0.25 s), but harmful in case deliberate vision of the beam.

- class 3: Lasers emitting radiation which may exceed the EMP in case of direct vision of the beam, but with relatively low risk of injury in most cases. We do not have this type of laser.

- class 4: Lasers for which vision in the beam and skin exposure are dangerous.Also, vision of diffuse reflections can be dangerous. A fire hazard is also often present with this kind of laser. They require wearing protective glasses.

Our lasers belong to the 2nd class as they are equipped as standard with a red dot pointer allowing to simulate work or start it at a determined place. The red dot pointer power being very low (less than one mw), it is not dangerous.

All our machines comply with CE standards and meet requirements of Machinery Directive 2006/42 / EC.

They are supplied with:

- a key switch to start the tube

- door safety systems immediatly stopping laser emission in case the laser compartment is opened.

- an easily accessible emergency stop button.

- a special safety window for absorption of the laser beam.

The two technologies are different in terms of wavelength (Fiber = 1.064 and Co2 = 10.64 micrometers).

Wavelength being more or less absorbed according to materials, laser source should be selected according to material nature and desired application (marking / engraving / cutting)

CO2 source

Marking: wood, paper, cardboard, leather, textile, ceramic, cork, anodized aluminum, lacquered metals.

Engraving: Wood, glass, paper, cardboard, leather, textile, mirror, stone, cork, lacquered metals, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam

Cutting: Wood, paper, cardboard, leather, textile, cork, PMMA, PA, PC, PE, PES, PET, PP, PS, PPS, Foam.

Fiber Source

Marking: colored paper, leather, textile, ceramic, aluminum, anodized aluminum, precious metals, Steel, brass, copper, titanium, stainless steel, PA, PBT, PC, PE, PES, PET, PE, PP, PS, PUR, Foam

Engraving: Mirror, Ceramic, aluminum, anodized aluminum, lacquered metals, precious metals, Steel, brass, copper, titanium, stainless steel.

Cutting: fine metals up to 0.5 mm

Wavelength of fiber lasers is 1,064 micrometers, with a very small beam diameter and a much higher power than a same power Co2 machine (about 100 times greater).

They are used for metal marking and engraving : stainless steel, silver, gold, brass, titanium ... and for high contrast marking on plastics but also on leather, textiles and paper.

They can also be used in thin metal cutting, for instance in for jewelery business : gold, silver,etc

Depending on processed material and application (engraving, marking or cutting), power should be adapted.

For plastic or metal marking applications, low power is necessary.

For engraving or cutting applications, higher power is advised.

Our technical department can make tests and determine the most suitable equipement for your products.

Our machine range is available in different powers and working surfaces:

- power from 20 to 50 w

- working sizes from 70 x 70 mm to 1000 x 500 mm

and different technologies depending on required productivity and automation level :

- OEM integrable in production lines

- Fiber mark Pro 3 in stand alone working station

- Pendulum fiber mark for a first level of automation

- Fiber Mark Pro Max I with indexed turn table

- Fiber Max Pro Max XY for a large marking surface.

Our range flexibility will allow us to find the right version complying with your specifications.

All our fiber lasers are equipped with galvanometric heads for beam guidage.

The head is "waterproof" and maintenance is almost non-existent. The only output lens should be cleaned regularly, but since it is located far from processed materiel, it does not get very dirty.

Expected life of laser source is several years (MTBM 100,000 hours).

Our lasers are safe for the operator.

There are several laser classes

- class 1: Lasers that are safe when used, even for direct vision of the beam over a long period and even when using telescopic optical devices.

- class 2: Lasers emitting from 400 nm to 700 nm wavelength visible radiation, harmless for temporary exposures (0.25 s), but harmful in case deliberate vision of the beam.

- class 3: Lasers emitting radiation which may exceed the EMP in case of direct vision of the beam, but with relatively low risk of injury in most cases. We do not have this type of laser.

- class 4: Lasers for which vision in the beam and skin exposure are dangerous.Also, vision of diffuse reflections can be dangerous. A fire hazard is also often present with this kind of laser. They require wearing protective glasses.

Our lasers belong to the 2nd class as they are equipped as standard with a red dot pointer allowing to simulate work or start it at a determined place. The red dot pointer power being very low (less than one mw), it is not dangerous.

All our machines comply with CE standards and meet requirements of Machinery Directive 2006/42 / EC.

They are supplied with:

- a key switch to start the tube

- door safety systems immediatly stopping laser emission in case the laser compartment is opened.

- an easily accessible emergency stop button.

- a special safety window for absorption of the laser beam.