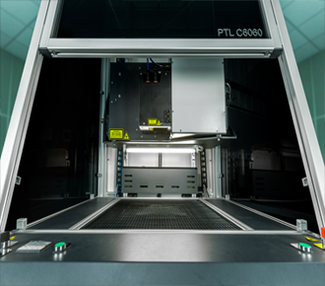

Speed, size, precision and versatility

using a C6060 3-axis laser

Applications

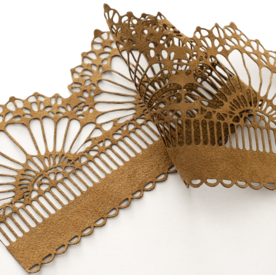

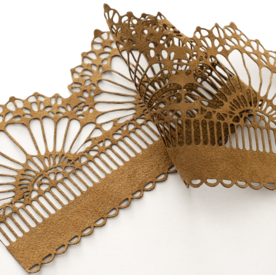

Leather cutting with a 3-axis laser : fashion, tailoring, decoration ...

Paper cutting or engraving : cards, scrap booking, announcements

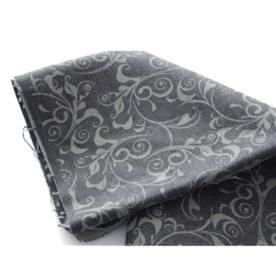

Leather and fabric engraving with a 3-axis co2 laser : clothing, fashion, decoration ...

Wood Engraving and cutting with a 3-axis laser : decoration, toy, industry, ...

Stencil cutting with a 3-axis co2 cutting laser: scrap, industry, ...

Engraving of fabrics with a 3-axis Co2 laser : fashion, scrap,

Leather cutting with a 3 axis co2 laser cutting machine : belts, bags, fashion items, ...

Paper / cardboard cutting with a 3-axis Co2 laser : card making, packaging, decoration ...with a 3-axis Co2 laser: card making, packaging, decoration ...

Applications

Leather cutting with a 3-axis laser : fashion, tailoring, decoration ...

Paper cutting or engraving : cards, scrap booking, announcements

Leather and fabric engraving with a 3-axis co2 laser : clothing, fashion, decoration ...

Wood Engraving and cutting with a 3-axis laser : decoration, toy, industry, ...

Stencil cutting with a 3-axis co2 cutting laser: scrap, industry, ...

Engraving of fabrics with a 3-axis Co2 laser : fashion, scrap,

Leather cutting with a 3 axis co2 laser cutting machine : belts, bags, fashion items, ...

Paper / cardboard cutting with a 3-axis Co2 laser : card making, packaging, decoration ...with a 3-axis Co2 laser: card making, packaging, decoration ...

Videos

Faq

The main advantage of a 3-axis Co2 laser is to combine the speed of a galvanometric head (much faster than a plotter type laser) and a large marking surface thanks to the movement of an optic (3rd axis) .

Main advantages are speed, precision, repeatability of movements allowing very high speed marking and possible integration into production chains.

The optical system of the galvanometric laser being placed into an hermetic head, it requires almost no maintenance . Galvanometric heads of our lasers are from of European leading manufacturers, which secures high reliability and durability of the system.

The versatile and user friendly software supplied with the machine allows to create customizable automatic sequences (date and time insertion , automatic incrementation, insertion of datas from external database ...) which is specially useful in case of integration into a production line

In galvanometric type lasers, the laser tube is placed above the head. The laser beam is guided by 2 integrated mirrors moved by servo motors.

Laser beam is focused by a lens whose characteristics determine the focal distance and, therefore, marking area and deflection angle.

As a result :

- engraving / marking / cutting surface is smaller (maximum 300 x 300 mm)

- When cutting thick materials, an important deflection angle is visible on material edges

- a large distance from the material does not allow to cut materials with important thickness

"plotter" type laser overcomes all these drawbacks with engraving surface related to machine size, small deflection angle and cutting of large thickness possible.

Materials are the same as for "plotter" lasers : wood, leather, fabrics, acrylic, plastic, stone, marble, metal, paper, cardboard ...

All can be marked or engraved according to laser power and speed.

Laser head being far from material, it is not possible to cut important thicknesses. In addition, the beam deflection angle induces an step effect (angle) on edges of the cut material.

"galvanometric" laser cuts fine materials: cardboard, plating, fabrics, leather, ... with the benefit of a very fast beam movement.

Our lasers are safe for the operator.

There are several laser classes

- class 1: Lasers that are safe when used, even for direct vision of the beam over a long period and even when using telescopic optical devices.

- class 2: Lasers emitting from 400 nm to 700 nm wavelength visible radiation, harmless for temporary exposures (0.25 s), but harmful in case deliberate vision of the beam.

- class 3: Lasers emitting radiation which may exceed the EMP in case of direct vision of the beam, but with relatively low risk of injury in most cases. We do not have this type of laser.

- class 4: Lasers for which vision in the beam and skin exposure are dangerous.Also, vision of diffuse reflections can be dangerous. A fire hazard is also often present with this kind of laser. They require wearing protective glasses.

Our lasers belong to the 2nd class as they are equipped as standard with a red dot pointer allowing to simulate work or start it at a determined place. The red dot pointer power being very low (less than one mw), it is not dangerous.

All our machines comply with CE standards and meet requirements of Machinery Directive 2006/42 / EC.

They are supplied with:

- a key switch to start the tube

- door safety systems immediatly stopping laser emission in case the laser compartment is opened.

- an easily accessible emergency stop button.

- a special safety window for absorption of the laser beam.

No, a laser is very easy to use and very intuitive.

Operator needs to create artwork on any graphics software (Coreldraw, Illustrator, Inskape, Autocad, Solidworks, ...), applying 2 main parameters to each color : laser speed and power according to expected result (material engraving ,half or complete cutting).

Then, the file is sent to laser.

It's as simple as that ! In a few minutes you can be up and running.

Note: speed and power parameters are linked to processed material. A parameter base is provided for a wide variety of materials to help you.

All of our lasers are delivered with on-site installation and training for efficient machine operation and maintenance

The main advantage of a 3-axis Co2 laser is to combine the speed of a galvanometric head (much faster than a plotter type laser) and a large marking surface thanks to the movement of an optic (3rd axis) .

Main advantages are speed, precision, repeatability of movements allowing very high speed marking and possible integration into production chains.

The optical system of the galvanometric laser being placed into an hermetic head, it requires almost no maintenance . Galvanometric heads of our lasers are from of European leading manufacturers, which secures high reliability and durability of the system.

The versatile and user friendly software supplied with the machine allows to create customizable automatic sequences (date and time insertion , automatic incrementation, insertion of datas from external database ...) which is specially useful in case of integration into a production line

In galvanometric type lasers, the laser tube is placed above the head. The laser beam is guided by 2 integrated mirrors moved by servo motors.

Laser beam is focused by a lens whose characteristics determine the focal distance and, therefore, marking area and deflection angle.

As a result :

- engraving / marking / cutting surface is smaller (maximum 300 x 300 mm)

- When cutting thick materials, an important deflection angle is visible on material edges

- a large distance from the material does not allow to cut materials with important thickness

"plotter" type laser overcomes all these drawbacks with engraving surface related to machine size, small deflection angle and cutting of large thickness possible.

Materials are the same as for "plotter" lasers : wood, leather, fabrics, acrylic, plastic, stone, marble, metal, paper, cardboard ...

All can be marked or engraved according to laser power and speed.

Laser head being far from material, it is not possible to cut important thicknesses. In addition, the beam deflection angle induces an step effect (angle) on edges of the cut material.

"galvanometric" laser cuts fine materials: cardboard, plating, fabrics, leather, ... with the benefit of a very fast beam movement.

Our lasers are safe for the operator.

There are several laser classes

- class 1: Lasers that are safe when used, even for direct vision of the beam over a long period and even when using telescopic optical devices.

- class 2: Lasers emitting from 400 nm to 700 nm wavelength visible radiation, harmless for temporary exposures (0.25 s), but harmful in case deliberate vision of the beam.

- class 3: Lasers emitting radiation which may exceed the EMP in case of direct vision of the beam, but with relatively low risk of injury in most cases. We do not have this type of laser.

- class 4: Lasers for which vision in the beam and skin exposure are dangerous.Also, vision of diffuse reflections can be dangerous. A fire hazard is also often present with this kind of laser. They require wearing protective glasses.

Our lasers belong to the 2nd class as they are equipped as standard with a red dot pointer allowing to simulate work or start it at a determined place. The red dot pointer power being very low (less than one mw), it is not dangerous.

All our machines comply with CE standards and meet requirements of Machinery Directive 2006/42 / EC.

They are supplied with:

- a key switch to start the tube

- door safety systems immediatly stopping laser emission in case the laser compartment is opened.

- an easily accessible emergency stop button.

- a special safety window for absorption of the laser beam.

No, a laser is very easy to use and very intuitive.

Operator needs to create artwork on any graphics software (Coreldraw, Illustrator, Inskape, Autocad, Solidworks, ...), applying 2 main parameters to each color : laser speed and power according to expected result (material engraving ,half or complete cutting).

Then, the file is sent to laser.

It's as simple as that ! In a few minutes you can be up and running.

Note: speed and power parameters are linked to processed material. A parameter base is provided for a wide variety of materials to help you.

All of our lasers are delivered with on-site installation and training for efficient machine operation and maintenance