Our range of pad printing machines for industial applications

in details

Models

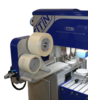

TTN 100 EKO SERIES - TTN90 EKO TE 1 colour pad printing machine - sealed ink cup

TTN 100 EKO SERIES - TTN 120 EKO 2 TC - 2 colour pad printing machine - sealed ink cups

TTN 100 SERIES - 1 or 2 colour pad printing machines - open ink cup

TTN 200 EKO SERIES 1 to 4 colour pad printing machines - Sealed ink cup

TTN 200 EKO SERIES 1 to 3 colour pad printing machines - Open ink cup

TTN 350 EKO SERIES - 2 to 6 colour pad printing machines - sealed ink cups

TTN 350 SERIES - 4 to 6 colour pad printing machines - open ink cup

Materials and supplies needed

UV exposure unit

UV unit for pad printing cliche or signage plate processing.

Working sizes : 254 x 305 mm.

The plate is exposed through a film to produce the printing pattern after polymerization and development.

The exposure unit is equipped with 4 tubes of 15 W, digital timer for exposure time control and foam system to keep film and cliche/plate in close contact.

UV GF exposure unit

GF UV unit is used to expose pad printing clichés or signage plates.

Working sizes = 550 x 350 mm.

It is equipped with 6 tubes of 20 W .

Exposure time is adjusted by a digital timer.

A vacuum system, by valve inflation, provides a close contact between film and cliche/plate.

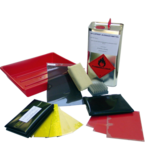

Pad printing inks

Wide choice of ink colours and types depending on the substrate to print

Additional products available, such as : Hardener, retarder, plate cleaner, object cleaner, cliches...

Cliches for pad printing

We can offer a large range of cliches: ST52 alcohol processed, LSL73 or WS 43 water processed, 0.5 steel etched or laser engraved cliches.

All are available in several sizes, for our own equipment as well as other machines.

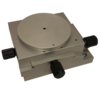

Silicon pads

Wide choice of silicone pad shapes, hardness or durability according to printed material.

Materials and supplies needed

UV exposure unit

UV unit for pad printing cliche or signage plate processing.

Working sizes : 254 x 305 mm.

The plate is exposed through a film to produce the printing pattern after polymerization and development.

The exposure unit is equipped with 4 tubes of 15 W, digital timer for exposure time control and foam system to keep film and cliche/plate in close contact.

UV GF exposure unit

GF UV unit is used to expose pad printing clichés or signage plates.

Working sizes = 550 x 350 mm.

It is equipped with 6 tubes of 20 W .

Exposure time is adjusted by a digital timer.

A vacuum system, by valve inflation, provides a close contact between film and cliche/plate.

Pad printing inks

Wide choice of ink colours and types depending on the substrate to print

Additional products available, such as : Hardener, retarder, plate cleaner, object cleaner, cliches...

Cliches for pad printing

We can offer a large range of cliches: ST52 alcohol processed, LSL73 or WS 43 water processed, 0.5 steel etched or laser engraved cliches.

All are available in several sizes, for our own equipment as well as other machines.

Silicon pads

Wide choice of silicone pad shapes, hardness or durability according to printed material.

Materials and supplies needed

UV exposure unit

UV unit for pad printing cliche or signage plate processing.

Working sizes : 254 x 305 mm.

The plate is exposed through a film to produce the printing pattern after polymerization and development.

The exposure unit is equipped with 4 tubes of 15 W, digital timer for exposure time control and foam system to keep film and cliche/plate in close contact.

UV GF exposure unit

GF UV unit is used to expose pad printing clichés or signage plates.

Working sizes = 550 x 350 mm.

It is equipped with 6 tubes of 20 W .

Exposure time is adjusted by a digital timer.

A vacuum system, by valve inflation, provides a close contact between film and cliche/plate.

Pad printing inks

Wide choice of ink colours and types depending on the substrate to print

Additional products available, such as : Hardener, retarder, plate cleaner, object cleaner, cliches...

Cliches for pad printing

We can offer a large range of cliches: ST52 alcohol processed, LSL73 or WS 43 water processed, 0.5 steel etched or laser engraved cliches.

All are available in several sizes, for our own equipment as well as other machines.

Silicon pads

Wide choice of silicone pad shapes, hardness or durability according to printed material.

Materials and supplies needed

UV exposure unit

UV unit for pad printing cliche or signage plate processing.

Working sizes : 254 x 305 mm.

The plate is exposed through a film to produce the printing pattern after polymerization and development.

The exposure unit is equipped with 4 tubes of 15 W, digital timer for exposure time control and foam system to keep film and cliche/plate in close contact.

UV GF exposure unit

GF UV unit is used to expose pad printing clichés or signage plates.

Working sizes = 550 x 350 mm.

It is equipped with 6 tubes of 20 W .

Exposure time is adjusted by a digital timer.

A vacuum system, by valve inflation, provides a close contact between film and cliche/plate.

Pad printing inks

Wide choice of ink colours and types depending on the substrate to print

Additional products available, such as : Hardener, retarder, plate cleaner, object cleaner, cliches...

Cliches for pad printing

We can offer a large range of cliches: ST52 alcohol processed, LSL73 or WS 43 water processed, 0.5 steel etched or laser engraved cliches.

All are available in several sizes, for our own equipment as well as other machines.

Silicon pads

Wide choice of silicone pad shapes, hardness or durability according to printed material.

Materials and supplies needed

UV exposure unit

UV unit for pad printing cliche or signage plate processing.

Working sizes : 254 x 305 mm.

The plate is exposed through a film to produce the printing pattern after polymerization and development.

The exposure unit is equipped with 4 tubes of 15 W, digital timer for exposure time control and foam system to keep film and cliche/plate in close contact.

UV GF exposure unit

GF UV unit is used to expose pad printing clichés or signage plates.

Working sizes = 550 x 350 mm.

It is equipped with 6 tubes of 20 W .

Exposure time is adjusted by a digital timer.

A vacuum system, by valve inflation, provides a close contact between film and cliche/plate.

Pad printing inks

Wide choice of ink colours and types depending on the substrate to print

Additional products available, such as : Hardener, retarder, plate cleaner, object cleaner, cliches...

Cliches for pad printing

We can offer a large range of cliches: ST52 alcohol processed, LSL73 or WS 43 water processed, 0.5 steel etched or laser engraved cliches.

All are available in several sizes, for our own equipment as well as other machines.

Silicon pads

Wide choice of silicone pad shapes, hardness or durability according to printed material.

Materials and supplies needed

UV exposure unit

UV unit for pad printing cliche or signage plate processing.

Working sizes : 254 x 305 mm.

The plate is exposed through a film to produce the printing pattern after polymerization and development.

The exposure unit is equipped with 4 tubes of 15 W, digital timer for exposure time control and foam system to keep film and cliche/plate in close contact.

UV GF exposure unit

GF UV unit is used to expose pad printing clichés or signage plates.

Working sizes = 550 x 350 mm.

It is equipped with 6 tubes of 20 W .

Exposure time is adjusted by a digital timer.

A vacuum system, by valve inflation, provides a close contact between film and cliche/plate.

Pad printing inks

Wide choice of ink colours and types depending on the substrate to print

Additional products available, such as : Hardener, retarder, plate cleaner, object cleaner, cliches...

Cliches for pad printing

We can offer a large range of cliches: ST52 alcohol processed, LSL73 or WS 43 water processed, 0.5 steel etched or laser engraved cliches.

All are available in several sizes, for our own equipment as well as other machines.

Silicon pads

Wide choice of silicone pad shapes, hardness or durability according to printed material.

Materials and supplies needed

UV exposure unit

UV unit for pad printing cliche or signage plate processing.

Working sizes : 254 x 305 mm.

The plate is exposed through a film to produce the printing pattern after polymerization and development.

The exposure unit is equipped with 4 tubes of 15 W, digital timer for exposure time control and foam system to keep film and cliche/plate in close contact.

UV GF exposure unit

GF UV unit is used to expose pad printing clichés or signage plates.

Working sizes = 550 x 350 mm.

It is equipped with 6 tubes of 20 W .

Exposure time is adjusted by a digital timer.

A vacuum system, by valve inflation, provides a close contact between film and cliche/plate.

Pad printing inks

Wide choice of ink colours and types depending on the substrate to print

Additional products available, such as : Hardener, retarder, plate cleaner, object cleaner, cliches...

Cliches for pad printing

We can offer a large range of cliches: ST52 alcohol processed, LSL73 or WS 43 water processed, 0.5 steel etched or laser engraved cliches.

All are available in several sizes, for our own equipment as well as other machines.

Silicon pads

Wide choice of silicone pad shapes, hardness or durability according to printed material.

Applications

Pad printing on metals : aluminum, stainless steel, brass ...

Pad printing on packaging : cardboard, wooden box, metal box ...

pad printing with En71 norm toys : tokens, pawns, buttons, dices

Pad printing on automotive parts : connectors, buttons, hoses ...

Pad printing on plastic: computers, keyboards, auto parts, covers ...

Promotional gifts marked with pad printing: mugs, pens, USB keys ...

Pad printing on cosmetics : bottles, tubes, etc.

Pad printing on medical items : cateters, syringes, masks ...

Pad printing on tools : hammers, screwdrivers, saw blades, ...

Pad printing on sports items : darts, golf or ping pong balls, ....

Marking on glass: bottles, ampoules, drinking glasses, ...

Pad printing in electronics industry : connectors, indicators, switch ...

Applications

Pad printing on metals : aluminum, stainless steel, brass ...

Pad printing on packaging : cardboard, wooden box, metal box ...

pad printing with En71 norm toys : tokens, pawns, buttons, dices

Pad printing on automotive parts : connectors, buttons, hoses ...

Pad printing on plastic: computers, keyboards, auto parts, covers ...

Promotional gifts marked with pad printing: mugs, pens, USB keys ...

Pad printing on cosmetics : bottles, tubes, etc.

Pad printing on medical items : cateters, syringes, masks ...

Pad printing on tools : hammers, screwdrivers, saw blades, ...

Pad printing on sports items : darts, golf or ping pong balls, ....

Marking on glass: bottles, ampoules, drinking glasses, ...

Pad printing in electronics industry : connectors, indicators, switch ...

Applications

Pad printing on metals : aluminum, stainless steel, brass ...

Pad printing on packaging : cardboard, wooden box, metal box ...

pad printing with En71 norm toys : tokens, pawns, buttons, dices

Pad printing on automotive parts : connectors, buttons, hoses ...

Pad printing on plastic: computers, keyboards, auto parts, covers ...

Promotional gifts marked with pad printing: mugs, pens, USB keys ...

Pad printing on cosmetics : bottles, tubes, etc.

Pad printing on medical items : cateters, syringes, masks ...

Pad printing on tools : hammers, screwdrivers, saw blades, ...

Pad printing on sports items : darts, golf or ping pong balls, ....

Marking on glass: bottles, ampoules, drinking glasses, ...

Pad printing in electronics industry : connectors, indicators, switch ...

Applications

Pad printing on metals : aluminum, stainless steel, brass ...

Pad printing on packaging : cardboard, wooden box, metal box ...

pad printing with En71 norm toys : tokens, pawns, buttons, dices

Pad printing on automotive parts : connectors, buttons, hoses ...

Pad printing on plastic: computers, keyboards, auto parts, covers ...

Promotional gifts marked with pad printing: mugs, pens, USB keys ...

Pad printing on cosmetics : bottles, tubes, etc.

Pad printing on medical items : cateters, syringes, masks ...

Pad printing on tools : hammers, screwdrivers, saw blades, ...

Pad printing on sports items : darts, golf or ping pong balls, ....

Marking on glass: bottles, ampoules, drinking glasses, ...

Pad printing in electronics industry : connectors, indicators, switch ...

Applications

Pad printing on metals : aluminum, stainless steel, brass ...

Pad printing on packaging : cardboard, wooden box, metal box ...

pad printing with En71 norm toys : tokens, pawns, buttons, dices

Pad printing on automotive parts : connectors, buttons, hoses ...

Pad printing on plastic: computers, keyboards, auto parts, covers ...

Promotional gifts marked with pad printing: mugs, pens, USB keys ...

Pad printing on cosmetics : bottles, tubes, etc.

Pad printing on medical items : cateters, syringes, masks ...

Pad printing on tools : hammers, screwdrivers, saw blades, ...

Pad printing on sports items : darts, golf or ping pong balls, ....

Marking on glass: bottles, ampoules, drinking glasses, ...

Pad printing in electronics industry : connectors, indicators, switch ...

Applications

Pad printing on metals : aluminum, stainless steel, brass ...

Pad printing on packaging : cardboard, wooden box, metal box ...

pad printing with En71 norm toys : tokens, pawns, buttons, dices

Pad printing on automotive parts : connectors, buttons, hoses ...

Pad printing on plastic: computers, keyboards, auto parts, covers ...

Promotional gifts marked with pad printing: mugs, pens, USB keys ...

Pad printing on cosmetics : bottles, tubes, etc.

Pad printing on medical items : cateters, syringes, masks ...

Pad printing on tools : hammers, screwdrivers, saw blades, ...

Pad printing on sports items : darts, golf or ping pong balls, ....

Marking on glass: bottles, ampoules, drinking glasses, ...

Pad printing in electronics industry : connectors, indicators, switch ...

Applications

Pad printing on metals : aluminum, stainless steel, brass ...

Pad printing on packaging : cardboard, wooden box, metal box ...

pad printing with En71 norm toys : tokens, pawns, buttons, dices

Pad printing on automotive parts : connectors, buttons, hoses ...

Pad printing on plastic: computers, keyboards, auto parts, covers ...

Promotional gifts marked with pad printing: mugs, pens, USB keys ...

Pad printing on cosmetics : bottles, tubes, etc.

Pad printing on medical items : cateters, syringes, masks ...

Pad printing on tools : hammers, screwdrivers, saw blades, ...

Pad printing on sports items : darts, golf or ping pong balls, ....

Marking on glass: bottles, ampoules, drinking glasses, ...

Pad printing in electronics industry : connectors, indicators, switch ...

Videos

Documentation

Download

-

Brochure commerciale tampographie automatique GB

-

Brochure commerciale tampographie automatique GB

-

Brochure commerciale tampographie automatique GB

-

Brochure commerciale tampographie automatique GB

-

Brochure commerciale tampographie automatique GB

-

Brochure commerciale tampographie automatique GB

-

Brochure commerciale tampographie automatique GB

Faq

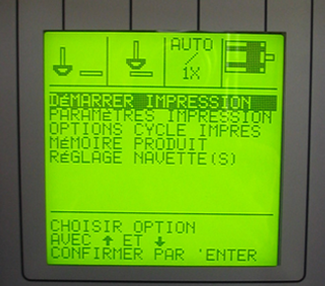

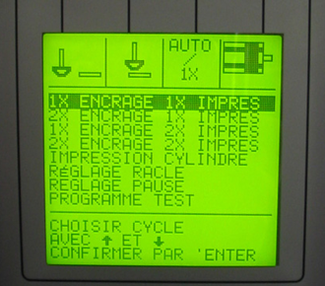

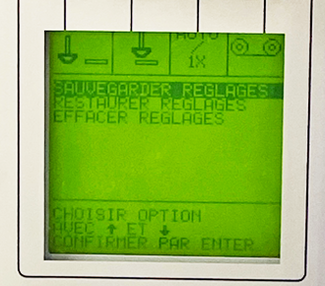

This range of machines is equipped with a print controller:

- user-friendly: access to all main machine adjustment functions through an intuitive machine/operator dialog (pictograms) in French/English.

- upgradeable: equipment can be upgraded with additional devices : number of colors, automatic pad cleaning system, corona treatment, integration into an automatic line. All these elements can be managed by the controller, via its additional available inputs /outputs

Universal range includes 4 machines: one color size 90 mm, one color size120 mm, two colors with or without independent cylinders.

Machines are not meant for integration into automatic systems. The PLC has a fixed configuration and it will not be able to control additional components: linear conveyor, turntable, dryer, padcleaning system ...

Industry range is upgradeable and it is possible for customer to integrate machine into an automatic line. With additional inputs / outputs available and improved electronics, the machine can control ancillary elements such as automatic loading system, corona treatment, turntable ...

Main interest of pad printing is the possibility to mark any substrate with adapted ink. A wide variety of inks is available : depending on the printed material type, it is just necessary to select proper ink.

Compared to other marking techniques, it is possible to print flat, concave or convex surfaces.

Pad printing machines can be easily automated for high production output.

Marking size is linked to inkcup size. For instance, a 90 mm diameter ink cup will allow a 80 mm diameter print, more is not possible.

Number of colors is linked to the number for printing heads. For instance, 2 printing heads will print 2 colors. Additional colors require multiple pass printing . For 4 colors, 2 colors should be printed on all items in a first pass, color changed inside inkcups and 2 other colors printed in a second pass. To avoid color overlapping, printed objects should be very precisely positioned.

Pad printing requires minimum quantities. For each printed pattern, it is necessary to produce the corresponding cliche (photoengraved photopolymer material).

The cost for cliche (related to its size) is amortized according to marking quantities.

For instance, for a 8 € cliché

- cliche cost for 10 prints is 0.80 / print

- cliche cost for 100 prints is 0.08 / print

Step 1: artwork design. Colors are separated in the graphics software (Illustrator, coreldraw, indesign ...)

2nd step :

- either cliche is directly engraved with a co2 or fiber laser. Go to step 4.

- either artwork is printed on a film with an inkjet printer, laser printer or flashing machine

Step 3: artwork is engraved in the cliche by UV exposure of the plate through the film / development / drying / post exposure

Step 4: Ink is prepared and poured in inkcup(s), cliche is placed in the machine.

Step 5: when marking position is adjusted, parts can be printed.

A one color hand operated machine can print up to 600 pcs / hour depending of easy part loading.

A one color semi automatic one (loading by operator) can print up to 900 pcs / hour depending of easy part loading.

For automatic machines, outputs are linked to automation system level.

It depends on material and ink types .

With some plastics, such as Abs, marking is dry to the touch 2-3 seconds later and printed product can be packed. However, perfect resistance ( abrasion, solvents ...) requires a few hours more.

Other materials such as glass, metal ... require a 48-72 hour drying time, that can be reduced by drying printed products at a high temperature.

This range of machines is equipped with a print controller:

- user-friendly: access to all main machine adjustment functions through an intuitive machine/operator dialog (pictograms) in French/English.

- upgradeable: equipment can be upgraded with additional devices : number of colors, automatic pad cleaning system, corona treatment, integration into an automatic line. All these elements can be managed by the controller, via its additional available inputs /outputs

Universal range includes 4 machines: one color size 90 mm, one color size120 mm, two colors with or without independent cylinders.

Machines are not meant for integration into automatic systems. The PLC has a fixed configuration and it will not be able to control additional components: linear conveyor, turntable, dryer, padcleaning system ...

Industry range is upgradeable and it is possible for customer to integrate machine into an automatic line. With additional inputs / outputs available and improved electronics, the machine can control ancillary elements such as automatic loading system, corona treatment, turntable ...

Main interest of pad printing is the possibility to mark any substrate with adapted ink. A wide variety of inks is available : depending on the printed material type, it is just necessary to select proper ink.

Compared to other marking techniques, it is possible to print flat, concave or convex surfaces.

Pad printing machines can be easily automated for high production output.

Marking size is linked to inkcup size. For instance, a 90 mm diameter ink cup will allow a 80 mm diameter print, more is not possible.

Number of colors is linked to the number for printing heads. For instance, 2 printing heads will print 2 colors. Additional colors require multiple pass printing . For 4 colors, 2 colors should be printed on all items in a first pass, color changed inside inkcups and 2 other colors printed in a second pass. To avoid color overlapping, printed objects should be very precisely positioned.

Pad printing requires minimum quantities. For each printed pattern, it is necessary to produce the corresponding cliche (photoengraved photopolymer material).

The cost for cliche (related to its size) is amortized according to marking quantities.

For instance, for a 8 € cliché

- cliche cost for 10 prints is 0.80 / print

- cliche cost for 100 prints is 0.08 / print

Step 1: artwork design. Colors are separated in the graphics software (Illustrator, coreldraw, indesign ...)

2nd step :

- either cliche is directly engraved with a co2 or fiber laser. Go to step 4.

- either artwork is printed on a film with an inkjet printer, laser printer or flashing machine

Step 3: artwork is engraved in the cliche by UV exposure of the plate through the film / development / drying / post exposure

Step 4: Ink is prepared and poured in inkcup(s), cliche is placed in the machine.

Step 5: when marking position is adjusted, parts can be printed.

A one color hand operated machine can print up to 600 pcs / hour depending of easy part loading.

A one color semi automatic one (loading by operator) can print up to 900 pcs / hour depending of easy part loading.

For automatic machines, outputs are linked to automation system level.

It depends on material and ink types .

With some plastics, such as Abs, marking is dry to the touch 2-3 seconds later and printed product can be packed. However, perfect resistance ( abrasion, solvents ...) requires a few hours more.

Other materials such as glass, metal ... require a 48-72 hour drying time, that can be reduced by drying printed products at a high temperature.

This range of machines is equipped with a print controller:

- user-friendly: access to all main machine adjustment functions through an intuitive machine/operator dialog (pictograms) in French/English.

- upgradeable: equipment can be upgraded with additional devices : number of colors, automatic pad cleaning system, corona treatment, integration into an automatic line. All these elements can be managed by the controller, via its additional available inputs /outputs

Universal range includes 4 machines: one color size 90 mm, one color size120 mm, two colors with or without independent cylinders.

Machines are not meant for integration into automatic systems. The PLC has a fixed configuration and it will not be able to control additional components: linear conveyor, turntable, dryer, padcleaning system ...

Industry range is upgradeable and it is possible for customer to integrate machine into an automatic line. With additional inputs / outputs available and improved electronics, the machine can control ancillary elements such as automatic loading system, corona treatment, turntable ...

Main interest of pad printing is the possibility to mark any substrate with adapted ink. A wide variety of inks is available : depending on the printed material type, it is just necessary to select proper ink.

Compared to other marking techniques, it is possible to print flat, concave or convex surfaces.

Pad printing machines can be easily automated for high production output.

Marking size is linked to inkcup size. For instance, a 90 mm diameter ink cup will allow a 80 mm diameter print, more is not possible.

Number of colors is linked to the number for printing heads. For instance, 2 printing heads will print 2 colors. Additional colors require multiple pass printing . For 4 colors, 2 colors should be printed on all items in a first pass, color changed inside inkcups and 2 other colors printed in a second pass. To avoid color overlapping, printed objects should be very precisely positioned.

Pad printing requires minimum quantities. For each printed pattern, it is necessary to produce the corresponding cliche (photoengraved photopolymer material).

The cost for cliche (related to its size) is amortized according to marking quantities.

For instance, for a 8 € cliché

- cliche cost for 10 prints is 0.80 / print

- cliche cost for 100 prints is 0.08 / print

Step 1: artwork design. Colors are separated in the graphics software (Illustrator, coreldraw, indesign ...)

2nd step :

- either cliche is directly engraved with a co2 or fiber laser. Go to step 4.

- either artwork is printed on a film with an inkjet printer, laser printer or flashing machine

Step 3: artwork is engraved in the cliche by UV exposure of the plate through the film / development / drying / post exposure

Step 4: Ink is prepared and poured in inkcup(s), cliche is placed in the machine.

Step 5: when marking position is adjusted, parts can be printed.

A one color hand operated machine can print up to 600 pcs / hour depending of easy part loading.

A one color semi automatic one (loading by operator) can print up to 900 pcs / hour depending of easy part loading.

For automatic machines, outputs are linked to automation system level.

It depends on material and ink types .

With some plastics, such as Abs, marking is dry to the touch 2-3 seconds later and printed product can be packed. However, perfect resistance ( abrasion, solvents ...) requires a few hours more.

Other materials such as glass, metal ... require a 48-72 hour drying time, that can be reduced by drying printed products at a high temperature.

This range of machines is equipped with a print controller:

- user-friendly: access to all main machine adjustment functions through an intuitive machine/operator dialog (pictograms) in French/English.

- upgradeable: equipment can be upgraded with additional devices : number of colors, automatic pad cleaning system, corona treatment, integration into an automatic line. All these elements can be managed by the controller, via its additional available inputs /outputs

Universal range includes 4 machines: one color size 90 mm, one color size120 mm, two colors with or without independent cylinders.

Machines are not meant for integration into automatic systems. The PLC has a fixed configuration and it will not be able to control additional components: linear conveyor, turntable, dryer, padcleaning system ...

Industry range is upgradeable and it is possible for customer to integrate machine into an automatic line. With additional inputs / outputs available and improved electronics, the machine can control ancillary elements such as automatic loading system, corona treatment, turntable ...

Main interest of pad printing is the possibility to mark any substrate with adapted ink. A wide variety of inks is available : depending on the printed material type, it is just necessary to select proper ink.

Compared to other marking techniques, it is possible to print flat, concave or convex surfaces.

Pad printing machines can be easily automated for high production output.

Marking size is linked to inkcup size. For instance, a 90 mm diameter ink cup will allow a 80 mm diameter print, more is not possible.

Number of colors is linked to the number for printing heads. For instance, 2 printing heads will print 2 colors. Additional colors require multiple pass printing . For 4 colors, 2 colors should be printed on all items in a first pass, color changed inside inkcups and 2 other colors printed in a second pass. To avoid color overlapping, printed objects should be very precisely positioned.

Pad printing requires minimum quantities. For each printed pattern, it is necessary to produce the corresponding cliche (photoengraved photopolymer material).

The cost for cliche (related to its size) is amortized according to marking quantities.

For instance, for a 8 € cliché

- cliche cost for 10 prints is 0.80 / print

- cliche cost for 100 prints is 0.08 / print

Step 1: artwork design. Colors are separated in the graphics software (Illustrator, coreldraw, indesign ...)

2nd step :

- either cliche is directly engraved with a co2 or fiber laser. Go to step 4.

- either artwork is printed on a film with an inkjet printer, laser printer or flashing machine

Step 3: artwork is engraved in the cliche by UV exposure of the plate through the film / development / drying / post exposure

Step 4: Ink is prepared and poured in inkcup(s), cliche is placed in the machine.

Step 5: when marking position is adjusted, parts can be printed.

A one color hand operated machine can print up to 600 pcs / hour depending of easy part loading.

A one color semi automatic one (loading by operator) can print up to 900 pcs / hour depending of easy part loading.

For automatic machines, outputs are linked to automation system level.

It depends on material and ink types .

With some plastics, such as Abs, marking is dry to the touch 2-3 seconds later and printed product can be packed. However, perfect resistance ( abrasion, solvents ...) requires a few hours more.

Other materials such as glass, metal ... require a 48-72 hour drying time, that can be reduced by drying printed products at a high temperature.

This range of machines is equipped with a print controller:

- user-friendly: access to all main machine adjustment functions through an intuitive machine/operator dialog (pictograms) in French/English.

- upgradeable: equipment can be upgraded with additional devices : number of colors, automatic pad cleaning system, corona treatment, integration into an automatic line. All these elements can be managed by the controller, via its additional available inputs /outputs

Universal range includes 4 machines: one color size 90 mm, one color size120 mm, two colors with or without independent cylinders.

Machines are not meant for integration into automatic systems. The PLC has a fixed configuration and it will not be able to control additional components: linear conveyor, turntable, dryer, padcleaning system ...

Industry range is upgradeable and it is possible for customer to integrate machine into an automatic line. With additional inputs / outputs available and improved electronics, the machine can control ancillary elements such as automatic loading system, corona treatment, turntable ...

Main interest of pad printing is the possibility to mark any substrate with adapted ink. A wide variety of inks is available : depending on the printed material type, it is just necessary to select proper ink.

Compared to other marking techniques, it is possible to print flat, concave or convex surfaces.

Pad printing machines can be easily automated for high production output.

Marking size is linked to inkcup size. For instance, a 90 mm diameter ink cup will allow a 80 mm diameter print, more is not possible.

Number of colors is linked to the number for printing heads. For instance, 2 printing heads will print 2 colors. Additional colors require multiple pass printing . For 4 colors, 2 colors should be printed on all items in a first pass, color changed inside inkcups and 2 other colors printed in a second pass. To avoid color overlapping, printed objects should be very precisely positioned.

Pad printing requires minimum quantities. For each printed pattern, it is necessary to produce the corresponding cliche (photoengraved photopolymer material).

The cost for cliche (related to its size) is amortized according to marking quantities.

For instance, for a 8 € cliché

- cliche cost for 10 prints is 0.80 / print

- cliche cost for 100 prints is 0.08 / print

Step 1: artwork design. Colors are separated in the graphics software (Illustrator, coreldraw, indesign ...)

2nd step :

- either cliche is directly engraved with a co2 or fiber laser. Go to step 4.

- either artwork is printed on a film with an inkjet printer, laser printer or flashing machine

Step 3: artwork is engraved in the cliche by UV exposure of the plate through the film / development / drying / post exposure

Step 4: Ink is prepared and poured in inkcup(s), cliche is placed in the machine.

Step 5: when marking position is adjusted, parts can be printed.

A one color hand operated machine can print up to 600 pcs / hour depending of easy part loading.

A one color semi automatic one (loading by operator) can print up to 900 pcs / hour depending of easy part loading.

For automatic machines, outputs are linked to automation system level.

It depends on material and ink types .

With some plastics, such as Abs, marking is dry to the touch 2-3 seconds later and printed product can be packed. However, perfect resistance ( abrasion, solvents ...) requires a few hours more.

Other materials such as glass, metal ... require a 48-72 hour drying time, that can be reduced by drying printed products at a high temperature.

This range of machines is equipped with a print controller:

- user-friendly: access to all main machine adjustment functions through an intuitive machine/operator dialog (pictograms) in French/English.

- upgradeable: equipment can be upgraded with additional devices : number of colors, automatic pad cleaning system, corona treatment, integration into an automatic line. All these elements can be managed by the controller, via its additional available inputs /outputs

Universal range includes 4 machines: one color size 90 mm, one color size120 mm, two colors with or without independent cylinders.

Machines are not meant for integration into automatic systems. The PLC has a fixed configuration and it will not be able to control additional components: linear conveyor, turntable, dryer, padcleaning system ...

Industry range is upgradeable and it is possible for customer to integrate machine into an automatic line. With additional inputs / outputs available and improved electronics, the machine can control ancillary elements such as automatic loading system, corona treatment, turntable ...

Main interest of pad printing is the possibility to mark any substrate with adapted ink. A wide variety of inks is available : depending on the printed material type, it is just necessary to select proper ink.

Compared to other marking techniques, it is possible to print flat, concave or convex surfaces.

Pad printing machines can be easily automated for high production output.

Marking size is linked to inkcup size. For instance, a 90 mm diameter ink cup will allow a 80 mm diameter print, more is not possible.

Number of colors is linked to the number for printing heads. For instance, 2 printing heads will print 2 colors. Additional colors require multiple pass printing . For 4 colors, 2 colors should be printed on all items in a first pass, color changed inside inkcups and 2 other colors printed in a second pass. To avoid color overlapping, printed objects should be very precisely positioned.

Pad printing requires minimum quantities. For each printed pattern, it is necessary to produce the corresponding cliche (photoengraved photopolymer material).

The cost for cliche (related to its size) is amortized according to marking quantities.

For instance, for a 8 € cliché

- cliche cost for 10 prints is 0.80 / print

- cliche cost for 100 prints is 0.08 / print

Step 1: artwork design. Colors are separated in the graphics software (Illustrator, coreldraw, indesign ...)

2nd step :

- either cliche is directly engraved with a co2 or fiber laser. Go to step 4.

- either artwork is printed on a film with an inkjet printer, laser printer or flashing machine

Step 3: artwork is engraved in the cliche by UV exposure of the plate through the film / development / drying / post exposure

Step 4: Ink is prepared and poured in inkcup(s), cliche is placed in the machine.

Step 5: when marking position is adjusted, parts can be printed.

A one color hand operated machine can print up to 600 pcs / hour depending of easy part loading.

A one color semi automatic one (loading by operator) can print up to 900 pcs / hour depending of easy part loading.

For automatic machines, outputs are linked to automation system level.

It depends on material and ink types .

With some plastics, such as Abs, marking is dry to the touch 2-3 seconds later and printed product can be packed. However, perfect resistance ( abrasion, solvents ...) requires a few hours more.

Other materials such as glass, metal ... require a 48-72 hour drying time, that can be reduced by drying printed products at a high temperature.

This range of machines is equipped with a print controller:

- user-friendly: access to all main machine adjustment functions through an intuitive machine/operator dialog (pictograms) in French/English.

- upgradeable: equipment can be upgraded with additional devices : number of colors, automatic pad cleaning system, corona treatment, integration into an automatic line. All these elements can be managed by the controller, via its additional available inputs /outputs

Universal range includes 4 machines: one color size 90 mm, one color size120 mm, two colors with or without independent cylinders.

Machines are not meant for integration into automatic systems. The PLC has a fixed configuration and it will not be able to control additional components: linear conveyor, turntable, dryer, padcleaning system ...

Industry range is upgradeable and it is possible for customer to integrate machine into an automatic line. With additional inputs / outputs available and improved electronics, the machine can control ancillary elements such as automatic loading system, corona treatment, turntable ...

Main interest of pad printing is the possibility to mark any substrate with adapted ink. A wide variety of inks is available : depending on the printed material type, it is just necessary to select proper ink.

Compared to other marking techniques, it is possible to print flat, concave or convex surfaces.

Pad printing machines can be easily automated for high production output.

Marking size is linked to inkcup size. For instance, a 90 mm diameter ink cup will allow a 80 mm diameter print, more is not possible.

Number of colors is linked to the number for printing heads. For instance, 2 printing heads will print 2 colors. Additional colors require multiple pass printing . For 4 colors, 2 colors should be printed on all items in a first pass, color changed inside inkcups and 2 other colors printed in a second pass. To avoid color overlapping, printed objects should be very precisely positioned.

Pad printing requires minimum quantities. For each printed pattern, it is necessary to produce the corresponding cliche (photoengraved photopolymer material).

The cost for cliche (related to its size) is amortized according to marking quantities.

For instance, for a 8 € cliché

- cliche cost for 10 prints is 0.80 / print

- cliche cost for 100 prints is 0.08 / print

Step 1: artwork design. Colors are separated in the graphics software (Illustrator, coreldraw, indesign ...)

2nd step :

- either cliche is directly engraved with a co2 or fiber laser. Go to step 4.

- either artwork is printed on a film with an inkjet printer, laser printer or flashing machine

Step 3: artwork is engraved in the cliche by UV exposure of the plate through the film / development / drying / post exposure

Step 4: Ink is prepared and poured in inkcup(s), cliche is placed in the machine.

Step 5: when marking position is adjusted, parts can be printed.

A one color hand operated machine can print up to 600 pcs / hour depending of easy part loading.

A one color semi automatic one (loading by operator) can print up to 900 pcs / hour depending of easy part loading.

For automatic machines, outputs are linked to automation system level.

It depends on material and ink types .

With some plastics, such as Abs, marking is dry to the touch 2-3 seconds later and printed product can be packed. However, perfect resistance ( abrasion, solvents ...) requires a few hours more.

Other materials such as glass, metal ... require a 48-72 hour drying time, that can be reduced by drying printed products at a high temperature.