Polyurethane and UV resins for domed labels

Add relief to your markings !

Materials and supplies needed

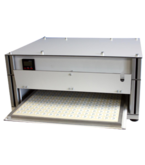

C80 Mixer-Degasser for Doming

For Polyurethane resin

It provides homogeneous mixing of polyurethane resin and hardener before their application on labels

- Mixing of the two components, from 60 to 400 g, achieved in less than 5 minutes

- Digital timer for precise control of mixing and degassing times

- Buzzer when cycle is completed

- Disposable container for mixing the two components

- Easy to use and maintenance free equipment.

E1000 Pneumatic dispenser for doming

For Polyurethane and UV resins :

Automatic digital model with 3 operating modes:

manual: Amount of dispensed product is controlled by a more or less long press on the pedal.

semi automatic: dispensing time is set to correspond to a label volume

automatic: time is set to dispense a label volume + interval before next label

Very innovative, it includes a "Teach" function taking into account the quantity of resin poured by operator and repeating the same quantity after validation. This "Teach" mode is also applicable for intervals, repeating pouring time defined during operator's gesture.

It also includes an anti-drop system by venturi effect preventing resin from flowing between 2 applications.

NOTE: the applicator requires an air compressor.

Storage trays for domed labels

For Polyurethane resin and UV resin

This is an important accessory for doming quality

Rigid, it keeps resin in horizontal position to avoid "spillage". Stackable, it protects labels from dust during drying.

Available in two sizes: 25 x 40 cm and 77 x 42 cm

Materials and supplies needed

E1000 Pneumatic dispenser for doming

For Polyurethane and UV resins :

Automatic digital model with 3 operating modes:

manual: Amount of dispensed product is controlled by a more or less long press on the pedal.

semi automatic: dispensing time is set to correspond to a label volume

automatic: time is set to dispense a label volume + interval before next label

Very innovative, it includes a "Teach" function taking into account the quantity of resin poured by operator and repeating the same quantity after validation. This "Teach" mode is also applicable for intervals, repeating pouring time defined during operator's gesture.

It also includes an anti-drop system by venturi effect preventing resin from flowing between 2 applications.

NOTE: the applicator requires an air compressor.

UV resin drying oven

This oven is only necessary for UV resin.

It allows resin polymerization in 10 minutes

Different sizes are available depending on your production requirements.

Applications

A new approach for tuning with doming : Motorcycle tank, hood, helmet...

Key rings with clear dome of polyurethane resin for proection and relief effect

3D signage: doming gives relief to your brand

Doming on a single or serie of labels : application of a polyurethane resin dome on a self-adhesive support

Labels, lettering, .. with polyurethane resin doming

Fast production for a warranted special effect ... marking in relief with doming

Vehicle, helmet, tank customization ... with outdoor resistant resin dome

With doming, catch attention with a 3 d effect marking

Set of domed labels for a mosaic with your brand

Doming on textiles, caps, luggage : for guaranteed effect compared to a simple print.

Attractive POS to promote your brand identification with doming

Original 3d effect license plate, relief obtained with doming resin

Domed labels in multiple uses to enhance your products.

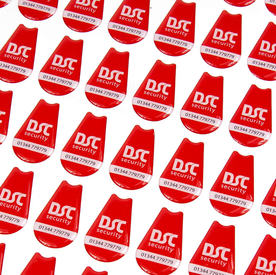

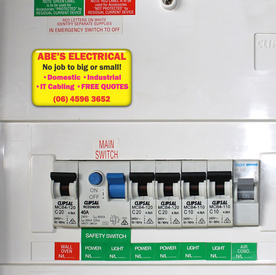

In professional uses quickly finding hotline number is essential : doming makes this easier.

Highlighted contact details by application of a clear resin dom on your logo

Boats, cars, equipment ... enhance your brand by magnifying glass effect of doming

Car, truck, equipment signatures with markings enhanced by doming

Applications

Easily find after sales service or commercial department contact information with a domed label

A clearly visible manufacturer for increased notoriety thanks to doming

Craftsmen, manufacturers, installers : a well marked domed product allows to identify you

Domed key rings: protective 3d look, giving a magnifying effect

Computers and accessories clearly identified, with beautiful effect of doming

Lettering, picto, logo, ... better visibility with a resin dome

With doming, catch attention with a 3 d effect marking

Domed labels for a 3d look on your products

Find a seller's name, easy and attractive with a domed label

Repair stores, service companies : your contact details clearly visible with a domed label

Domed key rings : the application of resin gives a 3d look

Coordinates, logo, brand clearly visible with doming 3 d effect

domed highlighted logo for panels, lettering, signage...

Logo, signage, pictogram in relief by doming effect.

Videos

Faq

The application of a clear resin dome makes the image not only unalterable, protecting it from scratches, dust, liquids, shocks ... but also more "intense" and attractive thanks to a three-dimensional effect.

Easy, fast and non-toxic, the process provides labels with real added value, unrelated to its implementation cost.

Doming can be applied on all shapes (square, round, oval ...) and many supports (adhesive materials, metals ...).

Our polyurethane (mixer, dispenser) or UV (dispenser, oven) doming equipments are intended for companies operating in labels, digital printing, printing ... business and wanting to add the opportunity of producing domed labels in an economical, easy and fast way.

We do not supply application robots because our customers want doming as a complementary activity to produce small-medium series (a few hundred) or unique copies.

Finally we offer the Fast Drop solution, without investment, with the main interest of fast processing for small series.

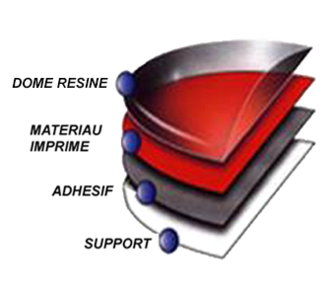

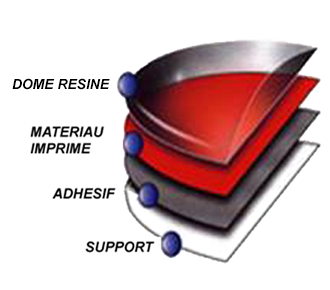

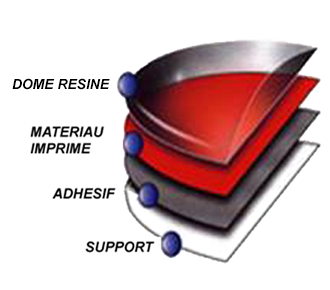

Doming / permavision/3D label, consists in applying a clear dome of resin on a printed label.

It is used in many fields because:

- it is resistant (8 years outdoors) and protects prints from UVs, bad weather (rain, snow, temperature ...), chemicals (solvents, petrol, ...)

- it creates a 3D lenticular effect (magnifying glass) on signage

- it highlights marking with a special visual impact. It catches the eye and makes you want to touch the product.

- it is flexible : depending on used resin, it can be applied on any flat, convex or concave form.

For faster processing, our system consists of economical disposable elements requiring no tool cleaning, no use of solvents ...

Resin and hardener mixture is produced in a disposable container in the automatic mixer.

Then, product is placed in a disposable syringe with disposable needle (diameter depending on the size of doming) for application, using a pneumatic applicator.

At the end of the operation, container, syringe and needle are discarded.

Polyurethane resin applied on labels durably protect them for an outdoor period of 8 years from

- UV rays: the resin dome avoids sign fading over time

- chemicals: resistance to solvents, cleaning products, fuel, ...

- scratching: the resin is flexible and returns to its original position after being stressed

- environmental damages: rain, snow, temperature ...

Doming resins are available with several qualities and characteristics:

- epoxy doming: with low cost but yellowing of labels over time. Outdoor use is not possible. We do not offer this type of resin.

- polyurethane doming: with outdoor resistance to weathering, UV rays ... we offer this type of resin, in different qualities : flexible and fluid (large signage), flexible and less fluid (for small signage), rigid.

- UV doming: with the main interest of a short drying time: 10 minutes. After application, resin is placed in a Uv oven and crosslinked (dried) in 10 minutes. We offer UV resin. Its cost price is more important.

Doming can finally be declined in several uses: olfactory doming (incorporation of an aroma), colored doming (addition of a dye), phosphorescent doming (addition of a photosphorescent pigment), thermochromic doming (pigment reacting to temperature), textile doming (for use on fabrics) ...

Several solutions are available for you

- polyurethane doming with two possible solutions : fast drop (no investment, to produce small series and prototyping) or conventional polyurethane equipment (mixer, dispenser, trays) for a low budget

- UV doming, requiring a low equipment investment (dispenser and UV oven).

All our solutions offer lettering and signage companies, large format printers and screenprinters the possibilty to produce domed label for low investment.

Temperature should be above 20 ° c. The higher the temperature, the faster the doming will dry.Humidity should be well controlled and be below 60%. Beyond bubbles may appear in labels.

Dust presence should be avoided , the slightest dirt will alter doming.

For semi automatic doming (polyurethane or UV) a compressor is necessary to operate the pneumatic applicator.

Several techniques can be used for printing your labels:

- laser: we have a range of medias for laser printing

- solvent inkjet : all main brands of solvent plotters allow printing compatible with doming

- flexography and offset : inkjet printing with water-based inks is not suitable for doming.

1 gr of mixture covers a 5-6 cm2 surface with a thickness of 1.8 mm.

Therefore, its is necessary to calculate the surface to coat and deduce the volume of resin-hardener to be mixed.

File preparation: always leave at least 1 mm between each label. Preferably work on small formats (A4). As far as possible, round corners and avoid cutting sharp-edged contours.

Printing: When inks are completely dry, carefully remove paper between labels without lifting label edges. Then flatten with a roller.

Cutting: Adjust the plotter cutting strength not to reach the paper backing, so that resin can spread over the label surface by capillary action then stop at the edges. If the backing paper is slightly cut, resin will tend to spread outside.

La résine UV présente un temps de séchage court (10 minutes) réalisé dans un four UV. Le mélange résine + durcisseur peut être réalisé à l'avance, stocké dans un frigo et utilisé à la demande. Après dépose sur les étiquettes, le support est polymèrisé sous l'effet de la lumière UV du four. 10 minutes après les étiquettes sont livrables.

En polyuréthane, avec l'emploi d'un four (étuve) de séchage , le temps de séchage est de 2h-2h30.

The application of a clear resin dome makes the image not only unalterable, protecting it from scratches, dust, liquids, shocks ... but also more "intense" and attractive thanks to a three-dimensional effect.

Easy, fast and non-toxic, the process provides labels with real added value, unrelated to its implementation cost.

Doming can be applied on all shapes (square, round, oval ...) and many supports (adhesive materials, metals ...).

Temperature should be above 20 ° c. The higher the temperature, the faster the doming will dry.Humidity should be well controlled and be below 60%. Beyond bubbles may appear in labels.

Dust presence should be avoided , the slightest dirt will alter doming.

For semi automatic doming (polyurethane or UV) a compressor is necessary to operate the pneumatic applicator.

Several techniques can be used for printing your labels:

- laser: we have a range of medias for laser printing

- solvent inkjet : all main brands of solvent plotters allow printing compatible with doming

- flexography and offset : inkjet printing with water-based inks is not suitable for doming.

Several solutions are available for you

- polyurethane doming with two possible solutions : fast drop (no investment, to produce small series and prototyping) or conventional polyurethane equipment (mixer, dispenser, trays) for a low budget

- UV doming, requiring a low equipment investment (dispenser and UV oven).

All our solutions offer lettering and signage companies, large format printers and screenprinters the possibilty to produce domed label for low investment.

Our polyurethane (mixer, dispenser) or UV (dispenser, oven) doming equipments are intended for companies operating in labels, digital printing, printing ... business and wanting to add the opportunity of producing domed labels in an economical, easy and fast way.

We do not supply application robots because our customers want doming as a complementary activity to produce small-medium series (a few hundred) or unique copies.

Finally we offer the Fast Drop solution, without investment, with the main interest of fast processing for small series.

For faster processing, our system consists of economical disposable elements requiring no tool cleaning, no use of solvents ...

Resin and hardener mixture is produced in a disposable container in the automatic mixer.

Then, product is placed in a disposable syringe with disposable needle (diameter depending on the size of doming) for application, using a pneumatic applicator.

At the end of the operation, container, syringe and needle are discarded.

Doming / permavision/3D label, consists in applying a clear dome of resin on a printed label.

It is used in many fields because:

- it is resistant (8 years outdoors) and protects prints from UVs, bad weather (rain, snow, temperature ...), chemicals (solvents, petrol, ...)

- it creates a 3D lenticular effect (magnifying glass) on signage

- it highlights marking with a special visual impact. It catches the eye and makes you want to touch the product.

- it is flexible : depending on used resin, it can be applied on any flat, convex or concave form.

File preparation: always leave at least 1 mm between each label. Preferably work on small formats (A4). As far as possible, round corners and avoid cutting sharp-edged contours.

Printing: When inks are completely dry, carefully remove paper between labels without lifting label edges. Then flatten with a roller.

Cutting: Adjust the plotter cutting strength not to reach the paper backing, so that resin can spread over the label surface by capillary action then stop at the edges. If the backing paper is slightly cut, resin will tend to spread outside.