Why Metalphoto ?

Approved when permanent identification is essential

Materials and supplies needed

UV Mark + exposure unit

Used for exposure of Metalphoto ®, Metalphoto Plus ®, Polycolor ® and IDMARK ® plates up to 254 x 305 mm format.

It is equipped with:

- A mechanical timer controlling lamp lighting and extinction,

- a light source and lamp power selector,

- an alveolar foam system ensuring close contact between film and exposed material.

UVMark GF+ exposure unit

Used for exposure of Metalphoto ®, Metalphoto Plus ®, Polycolor ® et ID MARK ® up to 305 x 508 mm.

It is equipped with:

- A digital timer with memory, controlling lamp lighting and the extinction and ringing when time over.

- A vacuum system to ensure close contact between film and exposed plate.

- a double exposure unit: ultraviolet tubes for Idmark and Polycolor / special tube for Metalphoto.

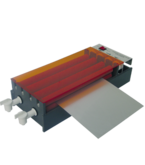

Metalphoto automatic processing machine

Motorized processing machine with adapted speed to ensure a regular development of Metalphoto ® plates.

Processing time is about 30 sec. for a 305 x 508 mm plate.

The machine features two zones: one to develop (developer), the other to fix (fixer) plates.

It is equipped with drain valves to collect chemicals after use as well as exclusive drive system ensuring simplified maintenance of the equipment.

Sealing tank

Meant for bringing to a boil sealing liquid used to close the structure of anodized plates.

Contains up to 4 plates of 305 x 508 mm.

Temperature control and start-up control unit.

The tank must be fixed with brackets to a load-bearing wall.

Materials and supplies needed

UV Mark + exposure unit

Used for exposure of Metalphoto ®, Metalphoto Plus ®, Polycolor ® and IDMARK ® plates up to 254 x 305 mm format.

It is equipped with:

- A mechanical timer controlling lamp lighting and extinction,

- a light source and lamp power selector,

- an alveolar foam system ensuring close contact between film and exposed material.

UVMark GF+ exposure unit

Used for exposure of Metalphoto ®, Metalphoto Plus ®, Polycolor ® et ID MARK ® up to 305 x 508 mm.

It is equipped with:

- A digital timer with memory, controlling lamp lighting and the extinction and ringing when time over.

- A vacuum system to ensure close contact between film and exposed plate.

- a double exposure unit: ultraviolet tubes for Idmark and Polycolor / special tube for Metalphoto.

Metalphoto automatic processing machine

Motorized processing machine with adapted speed to ensure a regular development of Metalphoto ® plates.

Processing time is about 30 sec. for a 305 x 508 mm plate.

The machine features two zones: one to develop (developer), the other to fix (fixer) plates.

It is equipped with drain valves to collect chemicals after use as well as exclusive drive system ensuring simplified maintenance of the equipment.

Sealing tank

Meant for bringing to a boil sealing liquid used to close the structure of anodized plates.

Contains up to 4 plates of 305 x 508 mm.

Temperature control and start-up control unit.

The tank must be fixed with brackets to a load-bearing wall.

Applications

Military industries : Metalphto withstands challenging environments: sea water spray, sand, humidity, UV for vehicle plates, bar codes, panels

Maritime container: due to its resistance properties, Metalphoto is approved by the Convention of Safe Containers

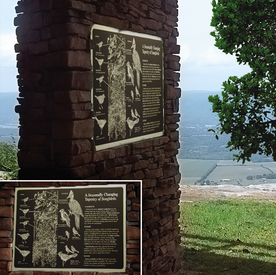

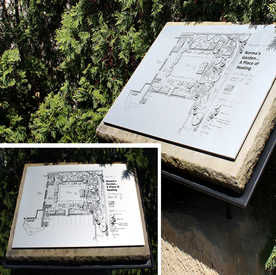

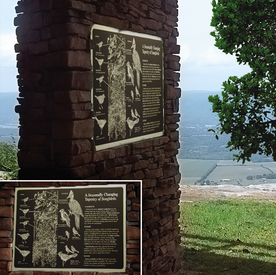

weather and vandalism resistance for outdoor routes : arboretum, fitness trail, signage ...

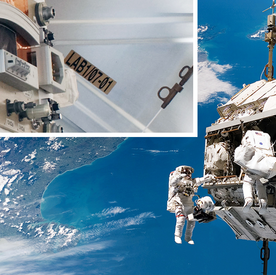

Logistics: traceability to all tests for shipping containers

Vehicle plates : resistance to solvents, petrol, skydrol ...

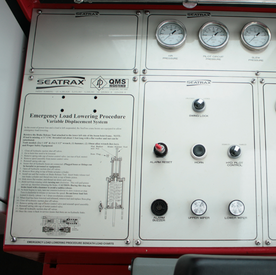

Shipbuilding: resistance to all tests for control panels, plates, instructions ...

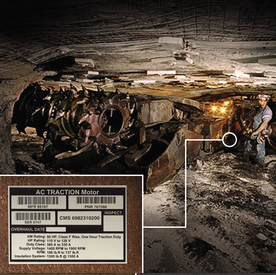

Mine: used for over 15 years by Caterpillar mine machines for its durabilty for plates, markings, diagrams ...

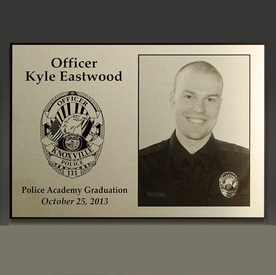

Commemoration, funeral : exceptional outdoor durability and photographic definition for funeral plaques, memorial, ...

Medical : smooth surface and resistance to sterilization or strong solvents for plates, bar codes ...

Petrol platforms: 35 years of resistance to sea water immersion and 20 years to UVS for plates, signs, bar codes

Heavy equipment: resistance to challenging environments for weight plates, manufacturer plates, instructions ...

Military vehicles : resistance to skydrol , kerosene, solvents .. for manufacturer's plates, IUID, signage ...

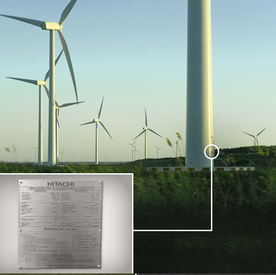

Renewable energy : resistance to UV rays, sea water spray, humidity... for panels, manufacturer's plates ...

Aviation: used since 1991 - Metalphoto secures durable signage for control panels...

Marine, Metalphoto withstands corrosion for 35 years: manufacturer's plates, bar codes, signage ...

Awards, monument signs, explanatory panels ...

Military use of Metalphoto: IUID, barcodes, nameplates, instructions...

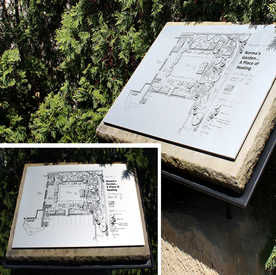

Outdoor and indoor signage : orientation panels, plans, ...

Military: ideal resistance to military environment constraints for IUID, traceability, notices

Space: Used since 1997 for traceability; Metalphoto combines durability with light weight for space applications.

Applications

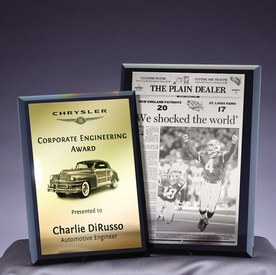

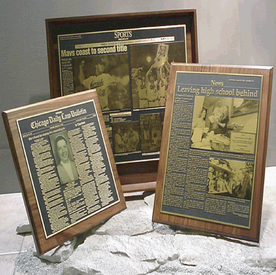

Newspaper articles, vehicle renovation, notices ... in Metalphoto Plus

Best employee /seller of the month, various awards ... in Metalphoto Plus

Rewards, awards, trophies, ... in classic gold Metalphoto Plus

Various awards , diplomas, ... in Metalphoto Plus

Labels, panels, funeral inters .... in Metalphoto Plus

Reproduction of articles, newspapers, literature ... in Metalphoto Plus

weather and vandalism resistance for outdoor routes : arboretum, fitness trail, signage ...

Commemoration, funeral : exceptional outdoor durability and photographic definition for funeral plaques, memorial, ...

Signs and arrows for park, gardens, arboretums, ... in Metalphoto Plus

Trophies, distinctions, awards ... in Metalphoto Plus

Awards, monument signs, explanatory panels ...

Outdoor signage for zoos, parks, gardens ... in Metalphoto Plus

Trophies, distinctions, awards ... in Metalphoto Plus

Outdoor and indoor signage : orientation panels, plans, ...

Videos

Faq

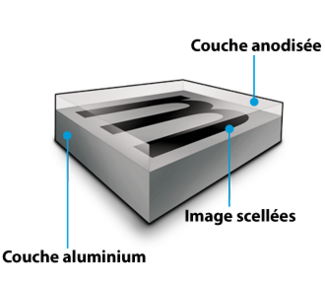

Metalphoto is an anodized photosensitive aluminum with special characteristics making it particularly suitable in fields where permanent identification is necessary (military, petroleum, chemical, medical, aeronautical industries ...) :

=> Resistant

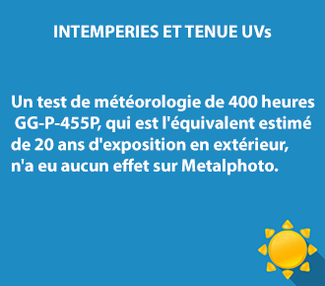

The image, trapped in the anodic layer, is impermeable to acids, mold, humidity (35 years warranty against corrosion), temperature variations (resistance to 400 ° C), most corrosive atmospheres and UV light (20 year outdoor warranty).

As a result, industrial groups recognize Metalphoto as the most resistant of existing aluminum processes.

=> Fast

No picture or screen is required between film and plate production

Cost effective from one to several thousands of custom items.

=> Accurate

Anything that can be photographed online or in halftone can be reproduced with absolute fidelity.

=> Easy

Few steps. Perfect results each time.

=> Safe

Complies with strictest environmental standards. Safe both for user and community.

=> Proven

Over 50 years of experience, thousands of users worldwide: US Army, Motorola, Boeing, NASA, Aerospace, Philips....

=> minimum investment

Economic and durable material.

Metalphoto is an aluminum plate with open pores containing silver salt that will turn to black (metallic silver) after exposure, development and fixation.

Metalphoto is available in aluminum:

- in 10 different thicknesses from 0.08 mm to 3.2 mm

- in 4 finishes: satin, mat, gloss, brushed

- in single-side (group 1) and double-side (group2)

- in Plus version: gold, sun fast gold, classic gold

No, producing Metalphoto is easy and inexpensive.

Once the film containing artwork is obtained (digital printing, inkjet printing ...) the Metalphoto plate is

- exposed through the film for a few seconds in the exposure unit

- placed inside the processing unit with rollers that will move it from development bath to fixing bath

- rinsed and immersed in a solution of boiling water for 10 minutes to seal aluminum pores

Then, plate is ready for shaping (cutting, machining ...)

A small working area (4-5 m2) is necessary for the production of Metalphoto.

The only necessary requirement is to work is an safe light conditions (red or yellow light) because Metalphoto is very sensitive to light.

The sealing tank area should be well ventilated or large enough to avoid condensation released by boiling water.

Metalphoto has been used for decades, to become a standard in each field it is used :

=> Medical:

Anodized aluminum has long been a standard for sterilization containers, control panels and other identification products in the surgical field.

Metalphoto photosensitive anodized aluminum complies with highest requirements, being resistant to heat, harsh chemicals and cleaning solvents. Ideal for sterile environments, Metalphoto does not harbor bacteria or corrode after thousands of sterilization cleaning cycles.

Metalphoto complies with several medical labeling requirements, including AAMI / CDV-1 ST79: 2010 / A2.06, a comprehensive guide to steam sterilization and sterilization insurance, and to the FDA Amendments Act of 2007 for the establishment of a unique device identification system (UDI)

=> Armament / Aeronautics / Defense:

For over 50 years, the United States Department of Defense has specified Metalphoto photosensitive anodized aluminum for durable labels, nameplates, diagrams and control panels used in harsh operating environments .

The United States Navy first adopted Metalphoto in 1958 for labels, signs and security control signs on board ships.

Since, Metalphoto has been integrated into several major Army weapon systems, including the Abrams tank, the Bradley combat vehicle and the HMMWV.

The Marine Corps and Army Depots both operate Metalphoto production facilities. All departments use Metalphoto for unique item identification barcode (IUID) labels as specified under MIL-STD-130.

=> Mining industry:

Used for over 15 years on Caterpillar mining equipment (Bucyrus), Metalphoto is designed to withstand demanding conditions of surface and underground mining.

Metalphoto photosensitive anodized aluminum is approved for mining identification applications, including approval plates (MSHA title 30, part 18.11), equipment diagrams / diagrams (MSHA title 30, part 70.310), machine control panels and several other applications.

Durable Metalphoto identification products support MSHA compliance, enable rapid and appropriate equipment repairs and improve operator efficiency.

For more than 50 years, industrial and military engineers have specified Metalphoto photosensitive anodized aluminum because of its ability to withstand harsh operating environments.

Metalphoto's exclusive technology permanently seals a UV stable image inside anodized aluminum; offering the confidence of unequaled durability, image resolution and readability.

=> Renewable energy:

Due to its ability to withstand harsh environmental conditions, Metalphoto is recommended for nameplates, inspection barcodes, maintenance schedules and other identifications used on solar, wind energy and hydroelectric systems.

Metalphoto meets a range of energy specifications, including OSHA 1910.145, National Electric Code (NEC) Article 690, ANSI Z535.4 and ISO 3864. Designed for permanence, Metalphoto does not fade and does not need to be replaced . If replacement is desired, Metalphoto is 100% recyclable.

-=>Transport / Logistics:

Metalphoto's exclusive technology permanently seals a UV stable image inside anodized aluminum, offering the guarantee of durability, image resolution and code readability.

Hyundai Translead specifies Metalphoto nameplates for shipping container nameplates conforming to ISO 6346 / BIC. Compared to traditional engraved stainless steel, Metalphoto withstands salt spray, sunlight and abrasion longer at a lower cost. Metalphoto complies with the Convention of Safe Containers Act, CSC Safety Approval Plate.

=> Architecture / Signage:

Since 1958, architects and designers have specified Metalphoto for high-value outdoor and indoor signage projects such as orientation panels, plan reproductions, building certification plaques

Metalphoto Photosensitive Anodized Aluminum allows to capture rich photographic-quality images inside the metal - providing unsurpassed longevity combined with modern, durable look of anodized aluminum. Because Metalphoto is a photographic process, its image resolution, sharpness and durability are superior to printed or engraved panels

The Metalphoto image is cleanable, resistant to graffiti and impervious to sunlight and abrasion.

=> Marine:

Specified for the first time by the United States Navy in 1958, Metalphoto has been performing in demanding marine applications for over 50 years.

Metalphoto's performance in marine applications is due to its unique combination of resistance to corrosion by salt water, UV / sun degradation, abrasion and many solvents.

Metalphoto's industrial curriculum vitae includes labels on ships, nameplates on shipping containers and control panels on offshore cranes.

=> Other standards available:

Industrial & Governmental approvals - Underwriters Laboratories / file N ° MH17767 - Canadian Standard Association / file N ° 11133-1, class N ° 7921 - Federal specification GGP-455 b, type I & II, grade A or B MILITARY APPROVALS - Mil-P -15024 F Mil-P-514 D - Mil-P-19834 B Mil-A-8625E

Equivalence DIN test standard - DIN 50017 - corrosion resistance - DIN 50021 - resistance to salt spray - DIN 50004 - resistance to Xenon attack - DIN 50018 - resistance to saturated industrial atmospheres - DIN 53387 - resistance to radiation artificial aging

Metalphoto is mainly used to produce Black and White images . Rastering features allow to get reproductions equivalent to photographic ones.

As long as Metalphoto plate is not sealed (immersed in boiling water for 10 minutes), aluminum pores remain open for adding color by screen printing technics.

However, exceptional durability of the Metalphoto will be valid for black part mainly, colored areas fading over time depending on their color and dye nature.

Metalphoto is an anodized photosensitive aluminum with special characteristics making it particularly suitable in fields where permanent identification is necessary (military, petroleum, chemical, medical, aeronautical industries ...) :

=> Resistant

The image, trapped in the anodic layer, is impermeable to acids, mold, humidity (35 years warranty against corrosion), temperature variations (resistance to 400 ° C), most corrosive atmospheres and UV light (20 year outdoor warranty).

As a result, industrial groups recognize Metalphoto as the most resistant of existing aluminum processes.

=> Fast

No picture or screen is required between film and plate production

Cost effective from one to several thousands of custom items.

=> Accurate

Anything that can be photographed online or in halftone can be reproduced with absolute fidelity.

=> Easy

Few steps. Perfect results each time.

=> Safe

Complies with strictest environmental standards. Safe both for user and community.

=> Proven

Over 50 years of experience, thousands of users worldwide: US Army, Motorola, Boeing, NASA, Aerospace, Philips....

=> minimum investment

Economic and durable material.

Metalphoto is an aluminum plate with open pores containing silver salt that will turn to black (metallic silver) after exposure, development and fixation.

Metalphoto is available in aluminum:

- in 10 different thicknesses from 0.08 mm to 3.2 mm

- in 4 finishes: satin, mat, gloss, brushed

- in single-side (group 1) and double-side (group2)

- in Plus version: gold, sun fast gold, classic gold

No, producing Metalphoto is easy and inexpensive.

Once the film containing artwork is obtained (digital printing, inkjet printing ...) the Metalphoto plate is

- exposed through the film for a few seconds in the exposure unit

- placed inside the processing unit with rollers that will move it from development bath to fixing bath

- rinsed and immersed in a solution of boiling water for 10 minutes to seal aluminum pores

Then, plate is ready for shaping (cutting, machining ...)

A small working area (4-5 m2) is necessary for the production of Metalphoto.

The only necessary requirement is to work is an safe light conditions (red or yellow light) because Metalphoto is very sensitive to light.

The sealing tank area should be well ventilated or large enough to avoid condensation released by boiling water.

Metalphoto has been used for decades, to become a standard in each field it is used :

=> Medical:

Anodized aluminum has long been a standard for sterilization containers, control panels and other identification products in the surgical field.

Metalphoto photosensitive anodized aluminum complies with highest requirements, being resistant to heat, harsh chemicals and cleaning solvents. Ideal for sterile environments, Metalphoto does not harbor bacteria or corrode after thousands of sterilization cleaning cycles.

Metalphoto complies with several medical labeling requirements, including AAMI / CDV-1 ST79: 2010 / A2.06, a comprehensive guide to steam sterilization and sterilization insurance, and to the FDA Amendments Act of 2007 for the establishment of a unique device identification system (UDI)

=> Armament / Aeronautics / Defense:

For over 50 years, the United States Department of Defense has specified Metalphoto photosensitive anodized aluminum for durable labels, nameplates, diagrams and control panels used in harsh operating environments .

The United States Navy first adopted Metalphoto in 1958 for labels, signs and security control signs on board ships.

Since, Metalphoto has been integrated into several major Army weapon systems, including the Abrams tank, the Bradley combat vehicle and the HMMWV.

The Marine Corps and Army Depots both operate Metalphoto production facilities. All departments use Metalphoto for unique item identification barcode (IUID) labels as specified under MIL-STD-130.

=> Mining industry:

Used for over 15 years on Caterpillar mining equipment (Bucyrus), Metalphoto is designed to withstand demanding conditions of surface and underground mining.

Metalphoto photosensitive anodized aluminum is approved for mining identification applications, including approval plates (MSHA title 30, part 18.11), equipment diagrams / diagrams (MSHA title 30, part 70.310), machine control panels and several other applications.

Durable Metalphoto identification products support MSHA compliance, enable rapid and appropriate equipment repairs and improve operator efficiency.

For more than 50 years, industrial and military engineers have specified Metalphoto photosensitive anodized aluminum because of its ability to withstand harsh operating environments.

Metalphoto's exclusive technology permanently seals a UV stable image inside anodized aluminum; offering the confidence of unequaled durability, image resolution and readability.

=> Renewable energy:

Due to its ability to withstand harsh environmental conditions, Metalphoto is recommended for nameplates, inspection barcodes, maintenance schedules and other identifications used on solar, wind energy and hydroelectric systems.

Metalphoto meets a range of energy specifications, including OSHA 1910.145, National Electric Code (NEC) Article 690, ANSI Z535.4 and ISO 3864. Designed for permanence, Metalphoto does not fade and does not need to be replaced . If replacement is desired, Metalphoto is 100% recyclable.

-=>Transport / Logistics:

Metalphoto's exclusive technology permanently seals a UV stable image inside anodized aluminum, offering the guarantee of durability, image resolution and code readability.

Hyundai Translead specifies Metalphoto nameplates for shipping container nameplates conforming to ISO 6346 / BIC. Compared to traditional engraved stainless steel, Metalphoto withstands salt spray, sunlight and abrasion longer at a lower cost. Metalphoto complies with the Convention of Safe Containers Act, CSC Safety Approval Plate.

=> Architecture / Signage:

Since 1958, architects and designers have specified Metalphoto for high-value outdoor and indoor signage projects such as orientation panels, plan reproductions, building certification plaques

Metalphoto Photosensitive Anodized Aluminum allows to capture rich photographic-quality images inside the metal - providing unsurpassed longevity combined with modern, durable look of anodized aluminum. Because Metalphoto is a photographic process, its image resolution, sharpness and durability are superior to printed or engraved panels

The Metalphoto image is cleanable, resistant to graffiti and impervious to sunlight and abrasion.

=> Marine:

Specified for the first time by the United States Navy in 1958, Metalphoto has been performing in demanding marine applications for over 50 years.

Metalphoto's performance in marine applications is due to its unique combination of resistance to corrosion by salt water, UV / sun degradation, abrasion and many solvents.

Metalphoto's industrial curriculum vitae includes labels on ships, nameplates on shipping containers and control panels on offshore cranes.

=> Other standards available:

Industrial & Governmental approvals - Underwriters Laboratories / file N ° MH17767 - Canadian Standard Association / file N ° 11133-1, class N ° 7921 - Federal specification GGP-455 b, type I & II, grade A or B MILITARY APPROVALS - Mil-P -15024 F Mil-P-514 D - Mil-P-19834 B Mil-A-8625E

Equivalence DIN test standard - DIN 50017 - corrosion resistance - DIN 50021 - resistance to salt spray - DIN 50004 - resistance to Xenon attack - DIN 50018 - resistance to saturated industrial atmospheres - DIN 53387 - resistance to radiation artificial aging

Metalphoto is mainly used to produce Black and White images . Rastering features allow to get reproductions equivalent to photographic ones.

As long as Metalphoto plate is not sealed (immersed in boiling water for 10 minutes), aluminum pores remain open for adding color by screen printing technics.

However, exceptional durability of the Metalphoto will be valid for black part mainly, colored areas fading over time depending on their color and dye nature.